Undoubtedly, high-quality oil is vital to ensuring a superior vaping experience. The nuances in flavors, consistencies, and effects from different compounds in oils can either make or break a consumer’s satisfaction with a product. By paring a properly handled oil with a flavor-enhancing cartridge like our quartz series, consumers can have a satisfying experience they will want to relive on the regular. However, it leads to the question: what is the intricate process involved in producing these oils, and which method would best suit your business?

Undoubtedly, high-quality oil is vital to ensuring a superior vaping experience. The nuances in flavors, consistencies, and effects from different compounds in oils can either make or break a consumer’s satisfaction with a product. By paring a properly handled oil with a flavor-enhancing cartridge like our quartz series, consumers can have a satisfying experience they will want to relive on the regular. However, it leads to the question: what is the intricate process involved in producing these oils, and which method would best suit your business?

Topics

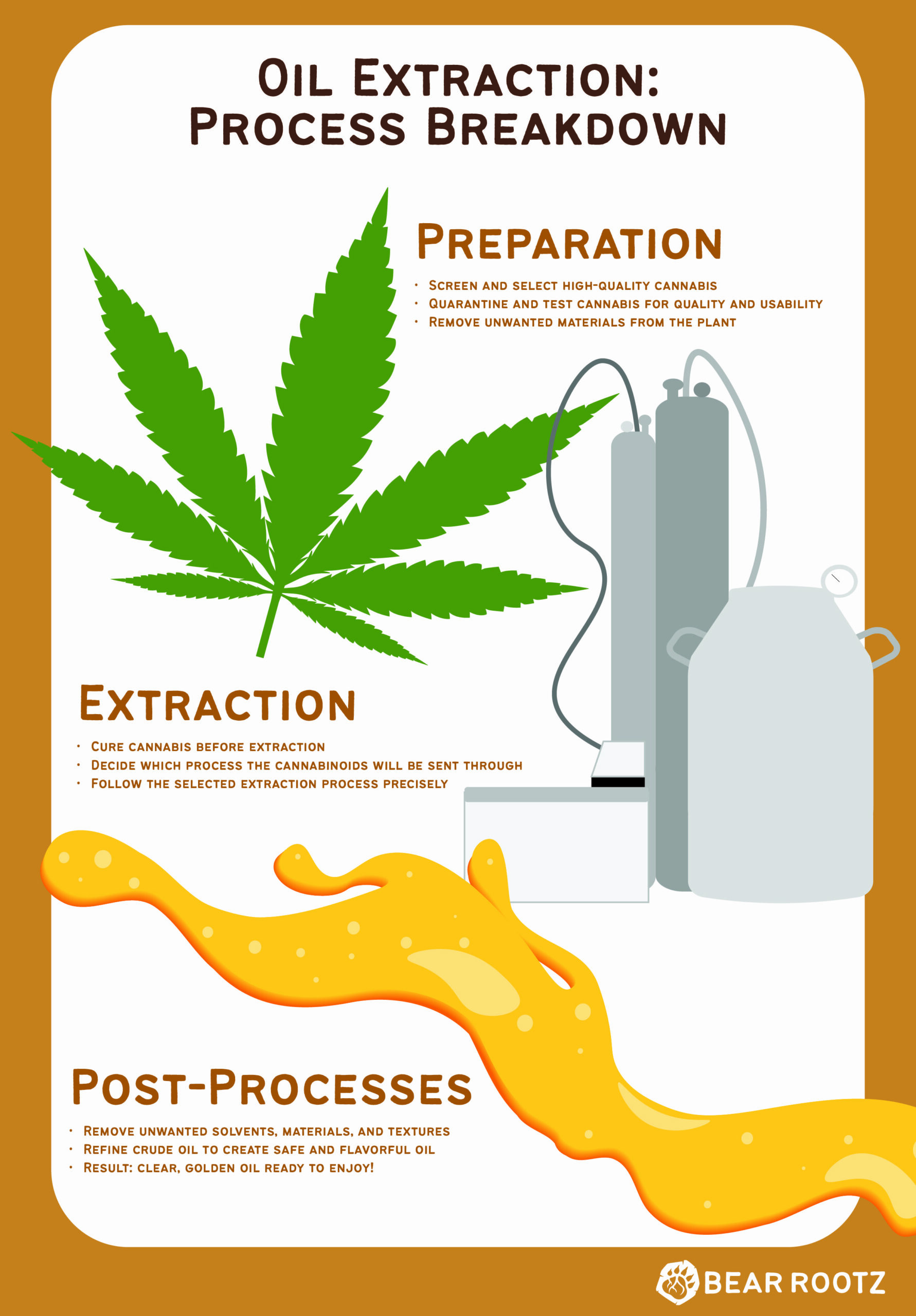

What Does Oil Extraction Entail?

The process of oil extraction ranges in complexity, some primitive extraction techniques have been historically used to create hash, or as simple as using two heated plates and pressure to create rosins. On the other end if this spectrum are very complex extraction processes, utilizing multiple different machines in sequences that involve meticulously separating cannabinoids, terpenes, and/or other beneficial compounds from the cannabis plant to ensure a high-quality targeted outcome and in some circumstances several post extraction refinement processes are included.

Extracting oil from these components can be done through various methods, with the selection usually depending on the extractor’s preference and the intended outcome. Upon consulting with professional extractors in the industry regarding these methods, a few processes have stood out among the rest.

Types of Extraction Methods

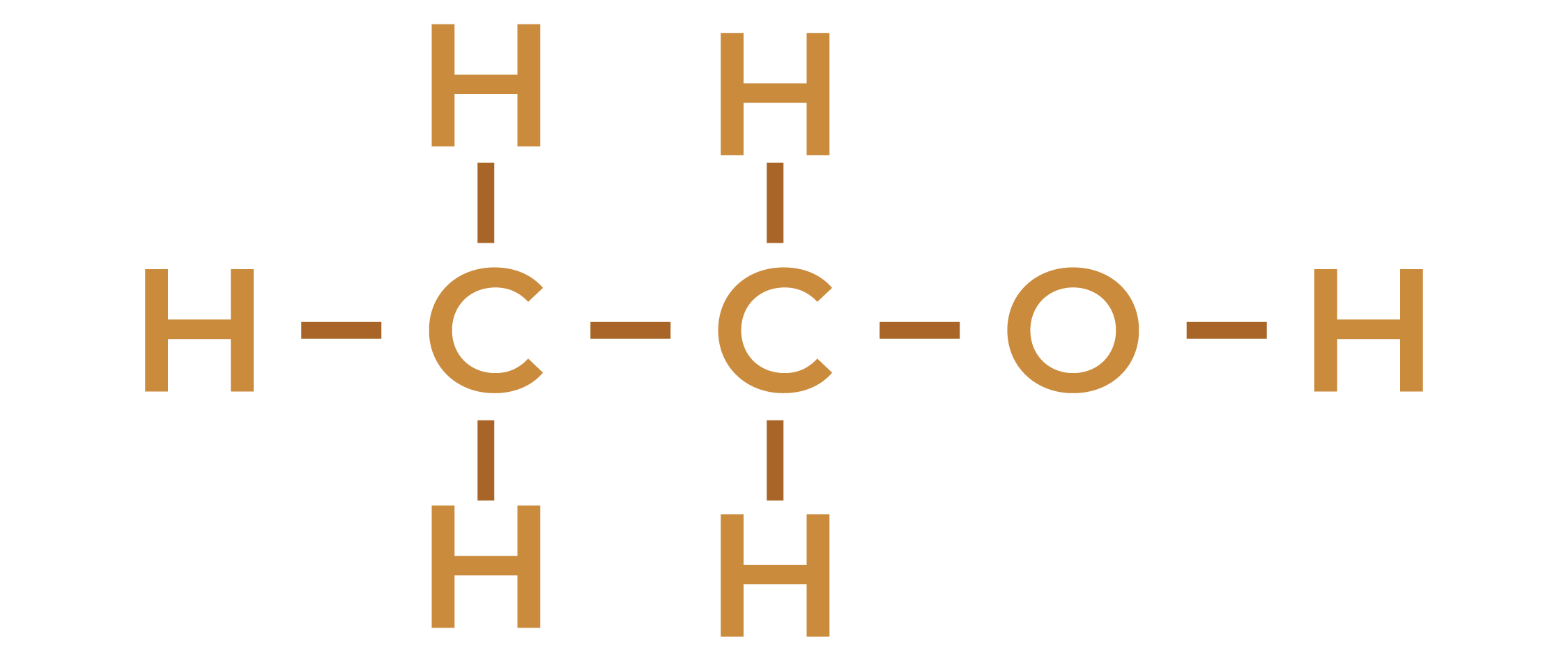

Ethanol Extraction

Ethanol extraction was one of the first common extraction methods named by multiple of our interviewed experts. Ethanol extraction requires introducing ethanol as a medium in the process to separate the targeted concentrate from the plant material and, once separated, enter a post-process that filters and purges the ethanol from the extract to begin creating the final oil we could find in cartridges [1]. This extraction method is favored by many companies because it’s commonly thought to be the most cost effective high volume extraction medium. Additionally the end result is generally considered to be high-quality and with minor biomass waste [2].

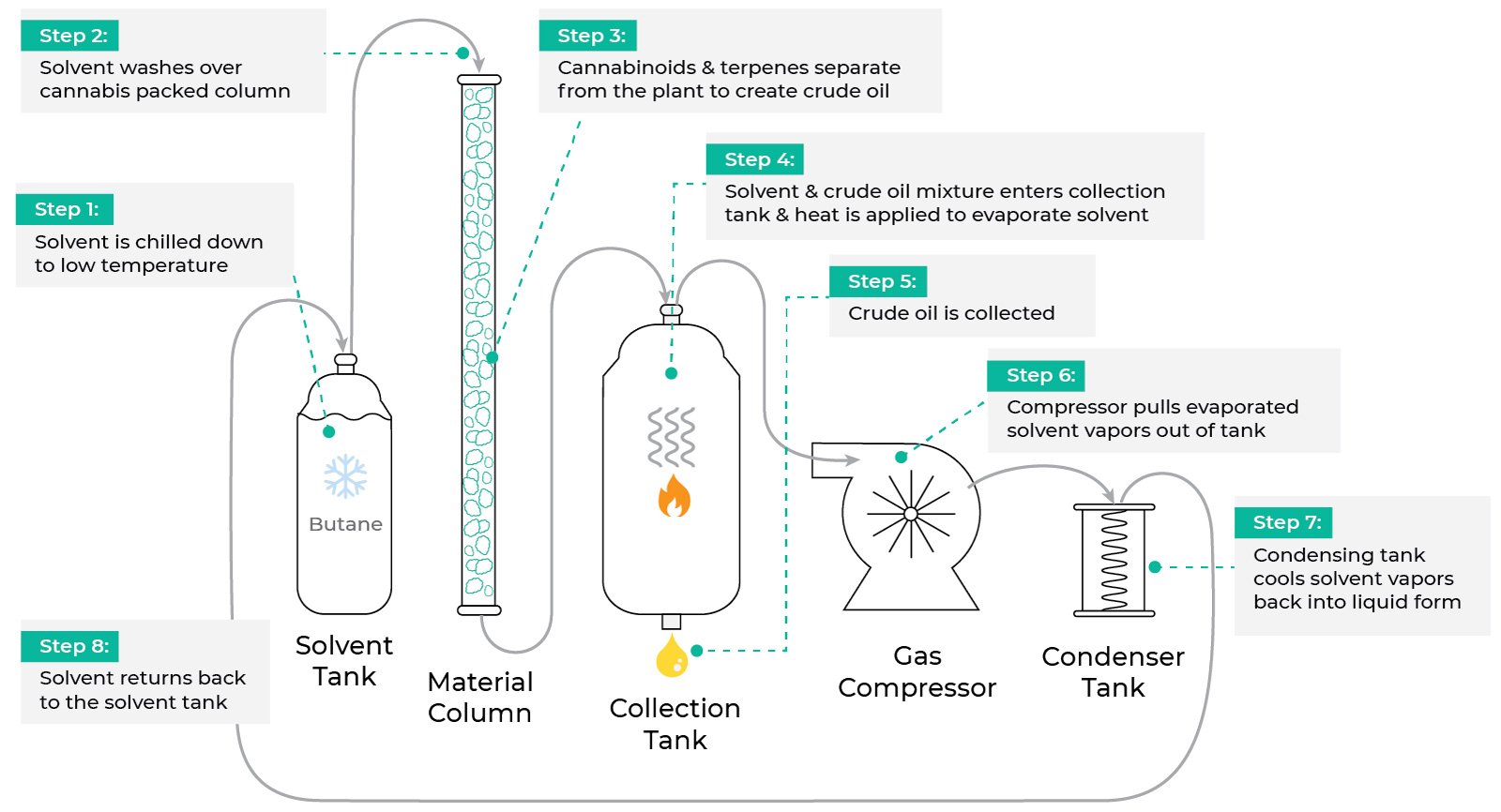

Hydrocarbon Extraction

Another popular technique used in the industry is hydrocarbon extraction, which entails using solvents like butane or propane on the raw material to strip-off compounds and gather terpenes. Following this, the materials undergo further refinement, removing the butane or propane and purging using machinery, such as a vacuum, to produce a safe oil for consumer use [3]. Much like ethanol extraction, this method is favored by extractors for its efficiency and minimal waste, making it a popular choice among different labs.

An overlook of the purging process in hydrocarbon extraction by Precision Extraction Solutions.

Distillation

One of the industries most common methods of creating oil for cartridges is the process of distillation with an end result commonly called “Distillate”. Distillation is a post-process technique favored by many extraction companies due to its ability to create very high percentage concentrates, and it provides companies additional versatility while being a relatively affordable process [4]. Typically used after butane or ethanol extraction methods, this process refines crude materials through a heated apparatus, separating the THC compound from the crude oil like “black goo-like” material found in cannabis crude extracts. This end result is the familiar golden oil found in cartridges. This distillate process can become a cycle to further refine oils when repeated on the out-put of a previous distillation batch. Often, terpenes are reintroduced to the oil to enhance its flavor and effects as the process of distillation typically strips off all terpenes found in crude extracts. Distillation is ideal for processing lower-quality products, as it can transform unusable or undesirable extracts into a desirable and usable end product.

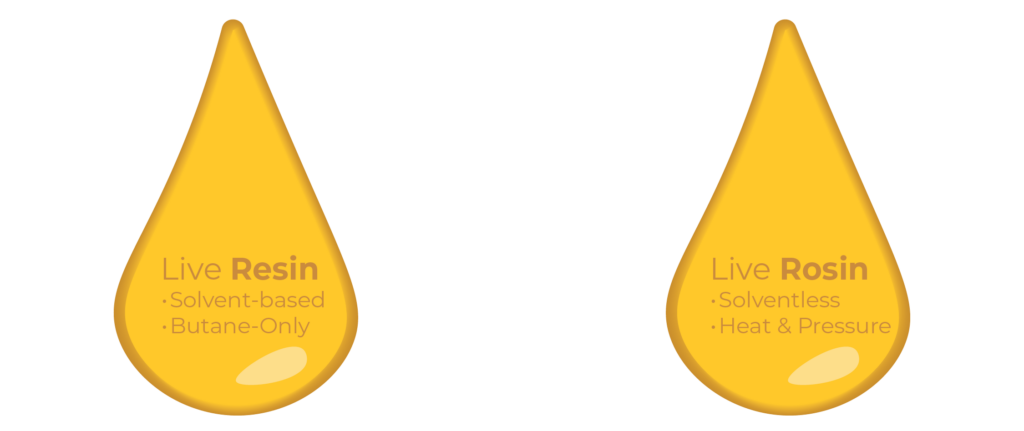

Live Resin

Live resin is a relatively new and increasingly popular process in the oil extraction industry. The process typically involves using flash-frozen cannabis biomass flower and performing a butane-only extraction, followed by a purging process that removes the butane and results in a more flavorful oil [5]. Additionally, the process of purging out the butane oil provides a de-carbing process simultaneously by converting the crystalline THCa in the extract into delta-9 THC, which helps prevent crystallization in the cartridge. To ensure optimal results, it’s crucial to use plants that have been immediately frozen, never dried out, and stored through cold-chain storage to prevent them from boiling off at room temperature, as the flavor comes from them. Our interviewed extractors highly praised live resin for its ability to produce the best flavor outcome that closely resembles the taste of the plant it comes from.

For a superior vaping experience, it is also recommended to use a high-quality device designed to handle a range of oil types and viscosities. Our quartz disposable or vape battery and quartz cartridge combo delivers a pure, flavorful experience thanks to the natural properties of quartz, which evenly heats the oil and enhances its flavor profile!

Live Rosin

One of the most highly regarded extraction methods by the extractors we interviewed is live rosin due to its ability to preserve the flavor of the raw material source in its oil compared to other methods. This method is solventless and involves using ice water to extract trichomes or hash from the dried-out plant, which is then sifted through screens to refine and filter THC-rich trichomes [5]. The resulting hash is then heated and pressurized, pressed through a filtered screen, and melted into an oil that does not crystallize in the cartridge. This method, like live resin, uses heat to convert THCa into delta-9 THC, creating a flavorful product that is praised by connoisseurs. However, one expert pointed out that it is more expensive than other methods due to its rarity, difficulty, and lower yield.

Plant Selection for High-Quality Cartridge Oil

When selecting the plant for oil extraction, it’s important to consider the maturity and oxidation exposure of the trichomes. The less terpenes are exposed to oxidation, the better the flavor in its oil! Even the scent of the selected biomass indicates the type of quality oil that will come from it. Terpenes are also sensitive to light, so keeping them away from UV light is recommended to maintain their quality when turning them into oil for cartridges.

Additionally, it is crucial to avoid applying excess heat or purging during any extraction method, as high temperatures and over-purging can cause terpenes to boil off quickly and result in the loss of flavor. Overall, it is best to keep the plant and extract as unadulterated as possible during any extraction process, and following the specified steps and precautions throughout any selected method can lead to a successful result.

Raw source material for oil extraction.

Best Extraction Practices

Ensuring quality and consistency in the oil extraction process is crucial regardless of the method used. Our interviewed experts suggest that the outcome of the product ultimately depends on the plant chosen and how it is treated, as well as the practices in the lab where the oil is produced. Shortcuts, ignorant inspections, and machinery misuse are what lead to low-quality oil with inferior flavor, so proper equipment and careful plant care before and during the extraction process are essential for creating the best-tasting cartridge oil consumers will enjoy.

Example of proper extraction equipment from Precision Extract Solutions.

In Conclusion

Choosing the best extraction method for your cartridge oil ultimately boils down to your desired outcome. According to the experts we interviewed, each extraction method has its benefits. Ethanol and hydrocarbon extraction both use solvents to produce high-quality oil through various filtering and post-processes while minimizing the waste of the plant material. Distillation is an affordable post-process option for turning unusable plant material like trim into high-quality oil that can be enjoyed by many consumers, making it a commonly used method in the industry. Live resin and live rosin extraction are more expensive and have lower oil returns when produced, but are highly praised by extractors for their fresh and well-preserved flavor and effects. Additionally, an extraction team that devotes to the proper handling of biomass, machinery use, and acquiring the proper certifications also ensures that the outcome meets high-quality standards. Ultimately, the quality of your oil is all a matter of how the preferred extraction process is carried from the beginnings of the plant’s growth, all the way to how it is packaged in a cartridge for consumers.

Sources:

[1] https://blog.lunatechequipment.com/ethanol-extraction-cannabis-hemp

[2] https://www.extractcraft.com/how-does-ethanol-extraction-work-for-botanical-extraction/

[3] https://precisionextraction.com/2019/08/what-is-hydrocarbon-extraction/

[4] https://blog.lunatechequipment.com/making-cannabis-distillate#:~:text=Short%20path%20distillation%20uses%20slow,collected%20in%20a%20collection%20flask

[5] https://greenpharms.com/resin-vs-rosin/#:~:text=Compared%20to%20resin%2C%20rosin%20is,created%20through%20a%20solventless%20method

Special thanks to the expert extractors who helped provide information for this article.