We consider this to be one of the most under deliberated topics of high importance to the success and scalability of cartridge companies. Cartridge capping machines, the sister machinery to a cartridge filling machine, has significant impacts on cartridge businesses which can be for the better or worse depending on which one is chosen.

There are costs or savings to be had in capital, time, labor and oil all to be considered when matching capping machinery to an operation.

A capping machine’s primary purpose is to secure the mouthpiece or tip to a cartridge tank, when these pieces are combined together (tip & tank) they are commonly referenced as a vape cartridge, like our C29 Cartridges for example.

First thing to note is that there are many brand options available when it comes to capping machines and most of these brands can be custom tailored to suit your specific business needs. But its worth initially acknowledging that capping machines come in three primary categories: manual, semi-auto and fully automated, The trick is to identify which style is suitable for your business. The core considerations are volume of carts, availability of staffing and of course budget and in this piece we get into more detail.

Topics

Factors to consider when looking for cartridge capping machines

First one must consider the size and scale of their operation. A smaller business with small production runs may not need larger, fully automated machines, while larger organizations will require high-volume output.

The materials, style, and type of mouthpieces also play a crucial role in determining the best machine for the job. One must consider the cost of the machine and the mouthpieces being used.

It’s also important to clarify if the mouthpieces being used for the cartridges are screw-on like our C5S Cartridges or press-on like our C6 Cartridges, as automatic capping machines are available for both options but not all machines are compatible with both types. This will ultimately impact which machine or machines a business could purchase because it may or may not work with the currently available stock and impact which type of mouthpieces they will be able to purchase and use in the future.

These machine companies typically have a “JIG” required for functional use which can be customized to your business’s particular cartridge needs. Make sure to discuss custom JIGs to match cartridges with your machine supplier at the outset to avoid costly mistakes where very expensive jigs turn into an unexpected repeat cost every time you update your cartridge.

Key Differences Between Capping Machines

Manual Arbor hand presses are the most basic option for capping cartridges and can cap several thousand units per day with the right operator. However, this method is time-consuming and requires a dedicated operator for each step of the process. On the other end of the spectrum automatic capping machines like the Thompson Duke TPM can cap up to 252 press-on mouthpieces simultaneously with just a couple of button presses which the daily output of these machines has far greater volume potential then the Manual Arbor alternative.

Automatic machines can minimize human error and inconsistencies but sometimes can also require complicated and detailed set-up. Manual machines combined with human error can lead to high levels of leakage, exposure to oxygen, and degradation of quality.

There are many different kinds of Arbor presses available, but many of the manual Arbor presses intended for capping cartridges typically have an adjustable or rotatable base to switch between different sizes of cartridges as well as different styles of mouthpieces. From there it is up to the operator to apply the correct amount of pressure to the lever attached to properly secure the mouthpiece to the cartridge.

SKMZ Arbor press for 0.5mL & 1mL oil cartridges

This is where many of the errors and discrepancies can arise, not enough pressure used can leave gaps between the mouthpiece and the cartridge, causing leakage and exposing the oil to oxygen and as a result, degradation of quality. On the other hand, too much pressure being used could also damage the cartridge or mouthpiece, thereby causing the same set of issues.

Once an operation reaches a certain level of output or production it may not be feasible to continue capping cartridges manually in order to continue growth and scaling. The more automated solutions such as the Thompson Duke TPM is capable of automatically capping up to 252 press-on mouthpieces onto disposable 510 cartridges at once with a two-button automatic control. [1]

Automatic capping machines minimize this human factor present in the process by automating much of the work. There are many different models and types of automatic capping machines but many operate under similar principles and processes. Typically an operator will set and adjust the pressure or torque to the correct amount needed either to press or screw-on the mouthpieces to the cartridges.

From there they can set the pre-filled cartridges into the designated area in the machine allowing the operator to affix the mouthpieces to the cartridges usually with just a few button presses, or even pedal presses in the case of some screw-on machines.

Due to each mouthpiece being given the same amount of force or torque because it is being applied automatically by the machine through internal calculations instead of by the guiding hand of an operator, there is less opportunity for too much or too little force or torque to be used, resulting in less waste and more consistency between carts.

Time Before Oil Degradation

There are multiple factors that play into the degradation and alteration of one’s concentrates and oils. Light, heat, and oxygen all play a role in the flavor and quality an oil will ultimately have. The unfortunate truth is that no matter what, oil or concentrate is going to slowly begin to degrade and change over time into something different to what you initially purchased. This is why proper handling and storage can go a long way in maintaining your high-quality vape product, and it all begins with the manufacturers and producers.

When it comes from a manufacturer’s point of view and capping filled carts, there are differences in exact acceptable minimum and maximum times between filling and capping a cartridge, but most seem to agree that you should always try to cap your filled cartridges as soon as possible to minimize waste and exposure to oxygen.

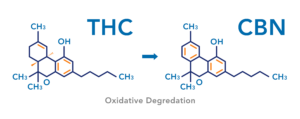

When oxygen reaches the THC or has prolonged exposure to it, it begins to break that THC down into what is known as CBN or Cannabinol. “CBN is a cannabinoid that is less psychoactive than THC, and is an oxidized form of THC that is known for its sedative effects.” [2] CBN naturally occurs in cannabis, though typical concentrations in refined oils are 1.5% or less. It isn’t unheard of to have slightly higher levels of CBN in a concentrate, especially if it is intentional to elicit certain responses or effects, but usually, 4% or more in a concentrate where it is not intentional might indicate poorly stored or aged cannabis with prolonged exposure to oxygen. [2]

Chemical formula degradation of THC into the cannabinoid CBN.

The level of CBN in a cannabis bud depends on its age and the amount of light and heat it has been exposed to. [3] As these chemical compounds begin to be affected by light, heat, and oxygen, they slowly change into compounds with vastly different structures, all of which have different flavor profiles, potencies, and consistencies, each with their own effects. This is why it is so important to properly store and heat everything from creation, through filling and capping of cartridges, all of the way into the hands of the consumer.

Compatibility With Different Mouthpiece Materials

It’s important to know and have a thorough understanding of which cartridges and mouthpieces you will be using prior to searching out a capping machine, whether looking for a manual hand press or an automated solution. As previously mentioned, there are two types of mouthpieces, though there are many different types of materials and styles they can be made of and into like the barrel polycarbonate style of our C101S Cartridges. Regardless all will either fall into the press-on or screw-on mouthpiece category.

Screw-on Mouthpieces on left, and Press-on Mouthpieces on right.

Unfortunately, automated capping machinery is usually built to work with a single type of mouthpiece. Machines are built with either the internal workings to exert a certain amount of force to the tops of mouthpieces or exert a certain amount of torque to rotate the mouthpiece onto the cartridge, not usually both.

Is it time to upgrade?

As mentioned previously, there may come a time when it is no longer feasible or cost-effective to have someone capping cartridges one or several at a time. Or perhaps the amount of wasted product or rate of error is quickly overshadowing the quality and consistency of a run. Automating more of the capping process could also free up an individual to both fill cartridges and jigs as well as run the capping machine instead of having two individuals for both jobs since capping will no longer be as time-consuming.

If production goals and revenues are consistently being fallen short of and are stifling potential growth, perhaps looking into the world of capping automation is worth it, provided the usually large financial investment needed to enter the world of automation can be met and is sustainable. Many of these machines can also take up a lot of real estate, so ensuring that your operation has sufficient room to house and use this machine should factor into your decision as well.

Thompson Duke “TPM” Automatic Press-on Machine.

Looking at types and costs of mouthpieces available to you also needs to be considered, perhaps you have been using screw-on mouthpieces but are looking to upgrade to a larger press-on style machine, is it going to be feasible and cost-effective for you and your brand to make the leap over to press-on style pieces vs screw-on?

As a smaller business, it’s important to understand that automating the capping procedure isn’t something that is a necessity, it’s something that should only be considered once the levels of volume, production, and capital investment are present and are consistently being met. Capping cartridges by hand may add more of a human factor into the equation, but in our opinion, we don’t necessarily think that’s a bad thing, having your hands on everything adds that bit of personal touch you’re not going to find when doing everything with automation.

Reliable Capping Machine Companies & Manufacturers

There are not only many different options to choose from when purchasing a capping and or filling machine, there are also many different manufacturers and producers out on the market today for businesses to choose from. We’d like to highlight just a few in order to help others have a starting point when beginning their journey into the capping world.

We want to note that just because we mention the following manufacturers doesn’t mean we endorse or promote them, these are just a few names that seemed to crop up repeatedly when speaking to others in the industry. We will always recommend doing your own research and follow-up in order to find what works best for you and your business.

Thompson Duke Industrial was a name we found being used time and time again when we spoke to other producers and businesses who have purchased and used several different kinds of capping machines, some of which were Thompson Duke Industrial brand, and others which weren’t. A handful of these individuals cited continuous use and praise of Thompson Duke capping machines for two simple reasons. The first was the ease of use and wide functionality across different types of materials and cartridges. The second was the use of simple mechanisms within these machines that seems to allow for easy diagnosis and repair should something go wrong or not work as intended.

Thompson Duke also carries the MPM capping machine which primarily focuses on screw-on type mouthpieces. Instead of applying a significant amount of force to the tops of cartridges, this machine operates by having the operator hold up the cartridge with a cap on top so that a rotating piece can apply enough torque in a specific direction in order to screw on the mouthpiece. [4] The trade-off here is that this requires the operator to hold up each individual cartridge, eliminating much of the automation, as a result, this machine is technically classified as a semi-automatic machine instead of automatic like the previously mentioned Thompson Duke TPM.

Thompson Duke MPM Semi-Automatic Press-on Mouthpiece Machine.

We found that though less common, there are other options available out there for screw-on mouthpiece automation, like the Ocitytimes automatic screw-on capping machine. [5] This machine allows the operator to set a jig full of filled carts down on a platform, and then an arm will begin to work its way around the set area, automatically applying a preset amount of torque to each mouthpiece, sealing each one individually. It seems that when it comes to automation, the capping industry leans heavily towards press-on mouthpieces again, for their ease of use and leak control, but also the sheer larger volume they are able to produce vs. using screw-on.

Ocitytimes Automatic 510 Thread Screw Mouthpiece Capping Machine.

Conclusion

In the course of our research, it seems that press-on mouthpieces are favored for several different reasons over their screw-on brothers. Some of these are that they are less prone to leaking vs screw-on mouthpieces, ease of use, and compatibility with most other capping machines on the market. They also allow for greater volumes of output due to the sheer speed, and efficiency by which many of these automated machines can press on these mouthpieces over their screw-on counterparts.

In conclusion, it’s important to do thorough research and consider various factors when choosing a cartridge capping machine, as the right machine can greatly impact the day-to-day operations and growth of a vape business. The vape industry is continuously evolving, and it’s important to stay up to date with the latest technologies and regulations as processes and machinery are refined and updated.

When it comes to the cartridge capping world, there are many options available to you, each with their own pros and cons. There is no universal answer to which machine or option is right for you and your business. Ultimately it will come down to looking at the other aspects of your business, time, space, money, types of materials, and volume of production all need to be considered because really the question we should be asking isn’t which machine is the best, it’s which machine is best for you and your business.

Sources:

[1] https://thompsondukeindustrial.com/store/tpm-mouthpiece-press.html

[2] https://brinstrument.com/blog/cannabis-distillation/cbn-an-oxygen-degradation-product-and-how-to-avoid-it/

[3] https://www.prospiant.com/how-to-extract-cbn-oil-cannabinoil/

[4] https://thompsondukeindustrial.com/mpm-mouthpiece-fastening-machine/

[5] https://www.ocitytimes.com/Automatic-510-Thread-Screw-Mouthpiece-Cartridge-Vape-Capping-Machine-by-Ocitytimes-pd45599081.html

Greetings! Very helpful advice within this post! It’s the little changes that make the most significant changes. Thanks a lot for sharing!

bookmarked!! I love your blog!

Awesome post, really looking forward to read more!

What a great blog, definitely will bookmark your site. Best Regards!

Great information in this one, definitely helped me make a decision on what I was looking for, appreciate the hard work!

Major thanks for the article post!

This site definitely has all of the information I need, keep it coming guys!

A lot of good info here, post more often though…lol!

A lot of blog writers out there nowadays, but only a handful with blog posts worth spending time on, nice job!

A-lot of good info here, wish you had gone a bit more in depth with some of the other big capping machine companies like Vape-Jet or Jupiter Research, but other than that, solid piece man.

Great blog, definitely bookmarking the site!

Nice analysis of the options available out there, thanks!

Bookmarked!

Fantastic read!

Respect to the author, fantastic info here!

Nice blog, you guys should think about doing more social media influencer collabs, be really cool to see the possibilities.

Precisely what I was looking for!

Exploring the latest trends and innovations in cannabis vaping, this blog offers invaluable insights for both novice and seasoned enthusiasts alike.

Really enjoyed this post! Good insights into cannabis vaping.

Great read, really appreciate the detailed breakdown!

Capping is a simple, yet crucial step for preserving freshness and potency, often overlooked, thanks for sharing!

Cappin’ those vape cartridges for maximum flavor and freshness!

This post brilliantly captures the little details and nuances of cartridge capping, thanks for shedding light on the subject!

Kudos to the author for such a helpful share!

Absolutely loved this post! Finally found the answers I’ve been looking for about cannabis vaping and cartridges. Thanks for the awesome content!

Appreciated the post, Thanks for shedding light on some industry info!

Seriously couldn’t stop reading! Your insights on spot-on. Thanks for such an engaging and informative post!