In recent years, the popularity of vaping cannabis oil has soared, with an increasing number of enthusiasts turning to vape pens like the Lotus, or All-in-One’s like the Nova Plus for a discreet and convenient way to enjoy the benefits of cannabinoids. Behind the scenes, however, lies a complex process that transforms raw cannabis into the potent and pure oil that fills those sleek cartridges. One of the most underlooked areas of this process is “pre-processing”, a crucial step that sets the stage for the quality and efficacy of the final product.

Some of the more commonly known oils are Live Resin, Sauce, Distillate, Liquid Diamonds, and Rosin, it’s crucial to recognize that each type may involve different processes and variations in pre-processing. Live resin may prioritize preserving the plant’s original flavor profile, while distillate undergoes extensive processing for purity. The nuances in pre-processing for each type play a pivotal role in achieving the desired characteristics.

As a cutting-edge vape technology business, providing advanced information is crucial. This guide is tailored to equip professionals with the most up-to-date knowledge on pre-processing in cannabis oil extraction. We’ll dive into not only the different types of oils but also the multiple “Pre-Processing” extraction areas, shedding light on the technical factors involved in the top five vape oil types: Live Resin, Sauce, Distillate, Liquid Diamonds, and Rosin.

Topics

Setting the Stage: Diving into the Foundations of Pre-Processing

The game of vape oil creation involves not just one but potentially multiple “Pre-Processing” extraction areas. The number of these areas can vary based on the extraction lab tech and the specific type of oil being created. It’s a nuanced field where different vape oils undergo distinct processes, emphasizing the need for tailored approaches.

Acknowledging the diversity in the vaping experience, it’s crucial to recognize that different types of oils require tailored pre-processing approaches. Live Resin, Sauce, Distillate, Liquid Diamonds, and Rosin each demand specific considerations during pre-processing to achieve the desired characteristics. Debates may arise on the necessity of tailoring pre-processing for different oil types. However, as we explore further, the technical intricacies will highlight why a customized approach is indispensable.

Before delving deeper, let’s clarify the term “Pre-Processing” in the context of vape oil creation. It encompasses the crucial steps taken before the actual extraction process begins, setting the stage for the quality and characteristics of the final product. Initial extraction yields what is known as crude oil extracts. For oils like distillate and other further refined vape oils, a second pre-processing stage comes into play. This stage is particularly crucial for achieving the desired purity and characteristics in the final product.

The ever-growing demand for high-quality vape products underscores the importance of staying at the forefront of technological advancements. Providing cutting-edge solutions requires a deep understanding of these pre-processing nuances and terminology.

Choosing the Right Starting Materials

In the intricate realm of cannabis oil extraction, the pivotal first step is the selection of the starting material. This seemingly straightforward decision holds the key to unlocking the full potential of cannabinoids and terpenes, laying the foundation for the creation of a potent and flavorful oil. This section delves into the science behind choosing the right starting material, emphasizing the importance of high-quality cannabis buds and trim rich in trichomes.

Understanding Trichomes

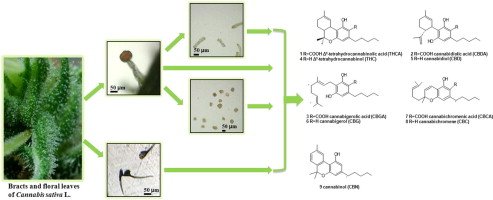

At the heart of cannabis potency and aroma lies the trichome, a microscopic resin-producing glandular structure found on the surface of cannabis plants. Trichomes are the treasure troves of cannabinoids, such as THC and CBD, as well as an array of aromatic terpenes. These compounds contribute to the therapeutic and psychoactive properties of the final oil product.

“Trichomes are the tiny, hair-like outgrowths that cover cannabis and hemp flower. They produce the valuable terpenes and cannabinoids like THC and CBD, that drive cannabis and hemp markets.” (“Chambers, Prospiant.com November 11, 2020) [1]

Figure 1a. – Laser dissected glandular trichomes from Cannabis sativa L. [2]

Cannabinoids and Terpene Concentration

Cannabinoids are a group of chemical compounds found in the cannabis plant that interact with the endocannabinoid system in the human body which is involved in regulating various psychological processes. [3]

Terpenes are a diverse class of organic compounds found in various plants, including cannabis. They are responsible for the distinct aromas and flavors associated with different strains of cannabis and play a significant role in the plant’s natural defense mechanisms and interactions with the environment. In cannabis, terpenes are synthesized in the same glands that produce cannabinoids, such as THC and CBD. They contribute to the overall effects of cannabis by interacting with cannabinoid receptors and other neurotransmitter systems in the body, a phenomenon known as the entourage effect.

The concentration of cannabinoids and terpenes within trichomes varies across different parts of the cannabis plant. High-quality cannabis buds and trim are particularly rich in trichomes, ensuring a more robust and diverse chemical profile in the extracted oil. This concentration is crucial for achieving the desired effects and flavor nuances in the final product.

Factors Influencing Starting Material Quality

Genetics & Cultivation Practices:

The genetic makeup of the cannabis strain plays a significant role in determining the composition of trichomes and, consequently, the chemical profile of the oil. Strains specifically bred for high cannabinoid and terpene content are preferred for optimal results. Environmental factors, nutrient levels, and cultivation techniques also help influence trichome development. Implementing best practices in cultivation, such as controlled environments and precise nutrient management, enhances the quality of the starting material.

The timing of the harvest is especially critical, harvesting at the peak of trichome development ensures maximal cannabinoid and terpene content. Late or premature harvesting may result in a suboptimal starting material, impacting the overall quality of the oil.

Selection Criteria for Premium Plant Material

Trichome Density:

The optimal starting material exhibits a high density of trichomes, indicating a greater concentration of cannabinoids and terpenes. This density is visually assessed, and experienced cultivators can gauge the quality based on the resinous appearance.

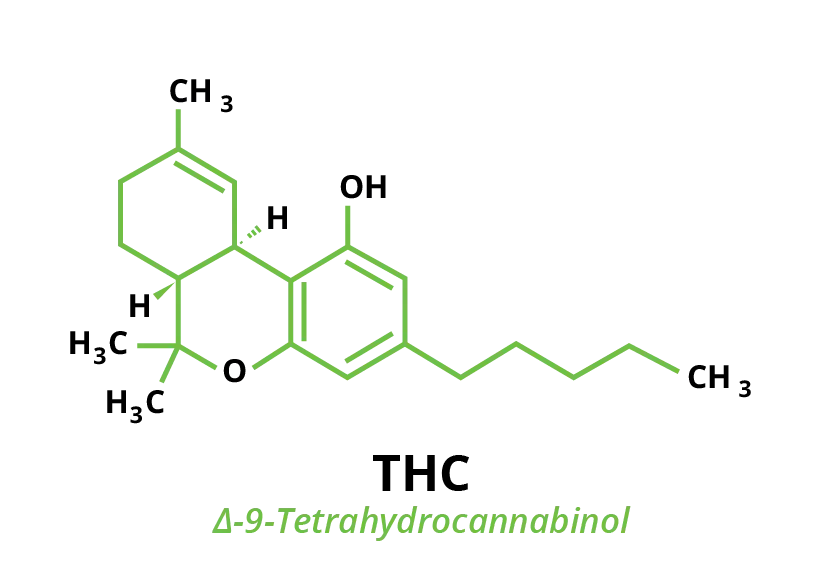

Figure 2a. – THC is the principal psychoactive constituent of cannabis and one of at least 113 total cannabinoids identified on the plant. [4]

Aroma Visual Inspection & Flavor Profile:

The aromatic profile of cannabis is a testament to its terpene content. Premium plant material emanates a rich and diverse aroma, foreshadowing the nuanced flavor profile that can be achieved through the extraction process. Visual inspection is an essential aspect of selecting the right starting material. Vibrant colors, well-formed buds, and an abundance of resin glands are indicators of a healthy and high-quality cannabis plant.

The scientific underpinnings of starting material selection involve a deep understanding of plant biology, genetics, and chemistry. Trichomes are complex biosynthetic factories where cannabinoids and terpenes are synthesized through intricate enzymatic pathways. The choice of starting material acts as a strategic decision to harness these natural processes for the optimal production of a biochemically rich cannabis oil.

Figure 3a. – Flowering Female Cannabis Plant.

In the scientific pursuit of crafting superior cannabis oil, the choice of starting material stands as a foundational pillar. By selecting premium cannabis buds and trim with an abundance of trichomes, cultivators and extractors set the stage for a meticulously crafted oil, ensuring a harmonious blend of cannabinoids and terpenes that epitomize the essence of the cannabis plant. This scientific approach to starting material selection is not merely a choice; it is a strategic step toward unlocking the full potential of cannabis for the ultimate oil production.

Grinding & Milling: Optimizing Surface Area for Enhanced Efficiency

The role of grinding and milling is a choreography of precision and science. This step, following the careful selection of cannabis material, is not merely a mechanical process; it is a strategic maneuver aimed at maximizing surface area exposure to the extraction solvent. This section delves into the nuanced world of grinding and milling, where the pursuit of uniform particle size becomes a key determinant of extraction efficiency.

Figure 1b. – Ground Cannabis Plant [5]

The Science of Grinding & Milling

Enhancing Surface Area:

The primary objective of grinding and milling is to break down the cannabis material into smaller particles, vastly increasing the overall surface area available for contact with the extraction solvent. This expanded surface area facilitates a more efficient extraction of cannabinoids and terpenes encapsulated within the plant matrix.

Extraction Solvent Interaction:

The extraction solvent, whether it be CO2, ethanol, or another medium, relies on direct contact with the cannabis material for optimal compound extraction. By reducing the material into finer particles, the solvent can permeate more effectively, reaching deeper into the plant structure and capturing a broader spectrum of bioactive compounds.

Factors Influencing Grinding & Milling Efficiency

Achieving a consistent particle size is paramount. Inconsistencies in size can result in uneven extraction, where some particles are over-extracted, leading to undesirable flavors or compound degradation, while others are under-extracted, compromising the overall potency and efficacy of the oil.

Figure 2b. – Output of Ground Cannabis using the Mobius M60. [6]

Equipment Selection:

The choice of grinding or milling equipment plays a pivotal role in determining particle size distribution. Different equipment, such as hammer mills, ball mills, or blade mills, has varying effects on the resulting particle sizes. Understanding the characteristics of each apparatus is crucial for tailored extraction processes.

Moisture Control, Duration & Speed:

The moisture content of cannabis material can impact its grinding behavior. Excessive moisture may lead to clumping, impeding the uniformity of particle size. Conversely, extremely dry material can be challenging to grind, necessitating careful moisture control for optimal results.

The duration and speed of the grinding or milling process influence the final particle size. Longer durations or higher speeds generally result in finer particles. Striking a balance is essential, as excessive grinding can generate heat, potentially compromising the integrity of sensitive compounds.

Particle Size Distribution & Extraction Efficiency

Microscopic Dynamics:

At the microscopic level, the interaction between the extraction solvent and cannabis material is a dynamic process influenced by particle size. Smaller particles offer a larger interface for solvent contact, fostering more efficient compound dissolution.

Extraction Kinetics:

The kinetics of extraction are intricately tied to particle size distribution. Smaller particles exhibit faster extraction rates, but there is a threshold beyond which diminishing returns may occur. Understanding these kinetics is crucial for optimizing the overall efficiency of the extraction process.

The scientific implications of grinding and milling in cannabis oil extraction extend beyond mere mechanical processing. It involves an understanding of materials science, fluid dynamics, and the intricate interplay between particle size and solvent interactions. This intersection of disciplines underscores the sophistication of the extraction process, elevating it from a mechanical procedure to a carefully orchestrated scientific endeavor.

By harnessing the principles of material science and fluid dynamics, cultivators and extractors can manipulate particle size to optimize surface area exposure and enhance extraction efficiency. This scientific approach to grinding and milling is not just about breaking down plant material; it is about orchestrating the perfect symphony of particle sizes to extract a harmonious blend of cannabinoids and terpenes, encapsulating the true essence of the cannabis plant in every drop of oil.

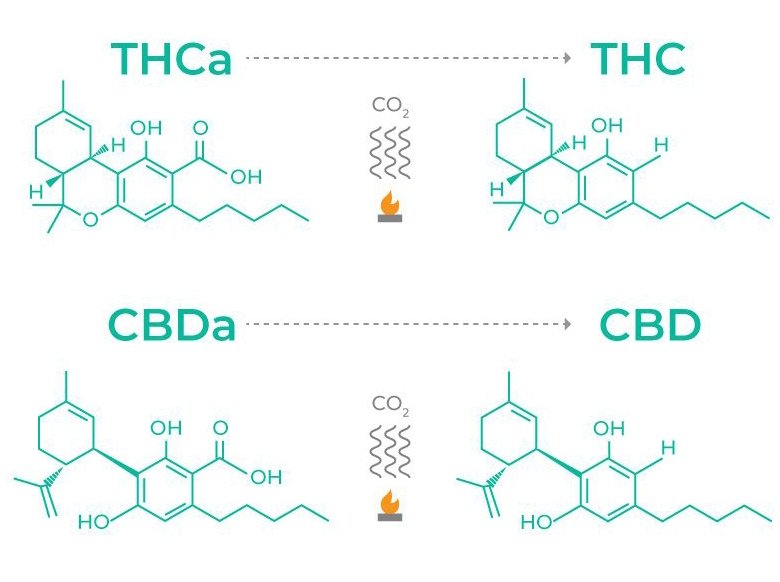

Decarboxylation in Cannabis Oil Production

The transformative step of decarboxylation is akin to alchemy, unlocking the hidden potential of raw cannabinoids. Raw cannabis, in its unadulterated form, harbors THCA and CBDA, precursors to the well-known THC and CBD. Decarboxylation, a nuanced thermal process, is the catalyst that propels these cannabinoids into their psychoactive and therapeutic forms. This section delves into the scientific intricacies of decarboxylation, revealing the alchemy behind the activation of compounds crucial for the desired effects in vape oil.

Figure 3b. – “THC, & CBD are formed by decarboxylation of their acidic forms during storage or through interaction with heat and light.” [7], [8]

For Live Resin, the focus on preserving terpenes requires meticulous temperature control. Sauce, with its high terpene content, demands a unique extraction approach. Distillate’s purity relies on advanced filtration techniques. Liquid Diamonds, emphasizing crystal formations, require precise solvent choices. Rosin, a solventless option, involves controlled pressure and heat. Critics may argue that such technical details are excessive. However, understanding these intricacies is the key to innovation, excellence, and providing the customer with quality products.

Understanding THCA & CBDA

Non-Psychoactive Precursors & Therapeutic Potential:

Raw cannabis synthesizes non-psychoactive acidic cannabinoids, namely THCA (tetrahydrocannabinolic acid) and CBDA (cannabidiolic acid). These compounds lack the potent effects associated with THC and CBD, respectively.

While THCA and CBDA offer potential therapeutic benefits, their non-psychoactive nature limits their direct impact. Decarboxylation is the key to unlocking the full therapeutic and psychoactive potential embedded within these precursor compounds.

Decarboxylation Process

Heat Activation & Temperature Dynamics:

Decarboxylation is fundamentally a chemical transformation, involving the removal of a carboxyl group from the acidic cannabinoids. This chemical metamorphosis is governed by the principles of organic chemistry, emphasizing the importance of precise conditions for optimal outcomes.

Decarboxylation involves subjecting cannabis material to heat, typically through controlled exposure to elevated temperatures. The application of heat initiates a chemical reaction that removes a carboxyl group (COOH) from THCA and CBDA, transforming them into THC and CBD.

The decarboxylation process is also highly temperature-dependent, different cannabinoids have distinct decarboxylation temperature ranges. THC, for instance, decarboxylates at a lower temperature than CBD. Precise temperature control is crucial to achieving optimal activation without compromising the integrity of the compounds.

The duration of heat exposure is also equally critical. Balancing temperature and time ensures a thorough and uniform decarboxylation process. Insufficient time may result in incomplete activation, while excessive heat exposure can lead to degradation of sensitive compounds.

Activation Kinetics & Bioavailability Enhancement:

The kinetics of decarboxylation are intricately tied to temperature and time. Understanding the rate at which carboxyl groups are shed and cannabinoids activated is pivotal for controlling the process and achieving the desired cannabinoid profile in the final product.

Activated cannabinoids, such as THC and CBD, possess enhanced bioavailability compared to their acidic precursors. Decarboxylation is thus pivotal for ensuring that the vape oil delivers cannabinoids in their most bioactive forms, optimizing the therapeutic and psychoactive effects upon inhalation. Vape oil formulations aim for consistency in effects. Decarboxylation standardizes the cannabinoid composition, allowing producers to create products with predictable and reproducible effects, meeting the expectations of consumers.

By unveiling the therapeutic and psychoactive properties inherent in acidic cannabinoids, this step holds the key to creating vape oils that deliver consistent and desired effects. The scientific understanding of decarboxylation is not just a procedural necessity; it is a strategic application of chemistry, kinetics, and temperature dynamics, ensuring that the alchemy of activation unfolds precisely in every drop of vape oil.

Removal of Impurities in Cannabis Oil Extraction

As the canvas of cannabis oil extraction is painted with the vibrant hues of cannabinoids and terpenes, the meticulous artistry of pre-processing comes into play, with a focus on the removal of impurities. Unwanted plant materials, including chlorophyll and waxes, possess the potential to overshadow the symphony of flavors and aromas in the final product.

This section unravels the technical intricacies of impurity removal in pre-processing, where precision becomes paramount for extracting cannabinoids and terpenes while leaving undesirable elements behind.

Figure 4a. – Cannabis Oil Processing Timeline. [9]

Factors Influencing Each Type of Oil

- Live Resin (Temperature and humidity control for preserving terpenes) – Temperature and humidity control are crucial factors in preserving terpenes, the aromatic compounds found in cannabis. Proper management of temperature prevents terpene degradation due to heat, while maintaining optimal humidity levels prevents mold growth and excessive evaporation of terpenes.

- Sauce (Extraction methods tailored to high terpene content) – By employing specialized techniques such as steam distillation or cold extraction, it’s possible to extract terpenes without subjecting them to excessive heat or pressure, thus retaining their full range of flavors and aromas. These tailored extraction methods result in products that offer a more robust sensory experience.

- Distillate (Advanced filtration techniques for achieving purity) – Employing advanced filtration techniques is paramount for achieving purity in cannabis distillates. These sophisticated methods, like short path distillation or molecular distillation, enable the separation and removal of contaminants and undesirable compounds, leaving behind a highly refined product rich in cannabinoids and terpenes.

- Liquid Diamonds (Precise solvent choices for crystal formations) – Selecting precise solvents is crucial for facilitating crystal formations in cannabis concentrates. By carefully choosing solvents with the right polarity and properties, such as hydrocarbons like butane or propane, extractors can encourage the formation of crystalline structures rich in cannabinoids and terpenes.

- Rosin (Controlled pressure and heat in solventless extraction) – Implementing controlled pressure and heat is critical in solventless extraction methods to produce high-quality rosin. By carefully calibrating the pressure and temperature parameters, extractors can efficiently release cannabinoids and terpenes from the plant material without the need for solvents.

Understanding Unwanted Plant Materials

Chlorophyll & Plant Waxes:

Chlorophyll, the green pigment responsible for photosynthesis, is abundant in cannabis plant material. While essential for plant health, its presence in extracts can contribute a grassy taste and a green hue, diminishing the overall quality of the oil.

Plant waxes, comprising lipids and other compounds, can also impart a waxy texture and undesirable flavors to the final product. Additionally, waxes may contribute to the clogging of vape pens and cartridges like the CQ6, affecting the user experience.

Precision in Impurity Removal

Selective Extraction & Solvent Choice:

The challenge in pre-processing lies in selectively extracting cannabinoids and terpenes while leaving impurities behind. This requires a nuanced approach, employing solvents and techniques that specifically target the desired compounds, ensuring minimal co-extraction of unwanted materials.

The choice of solvent is critical in achieving precision in impurity removal. Selective solvents with affinities for cannabinoids and terpenes, but not chlorophyll and waxes, are employed. Common solvents include butane, CO2, and ethanol, each offering unique advantages in the extraction process.

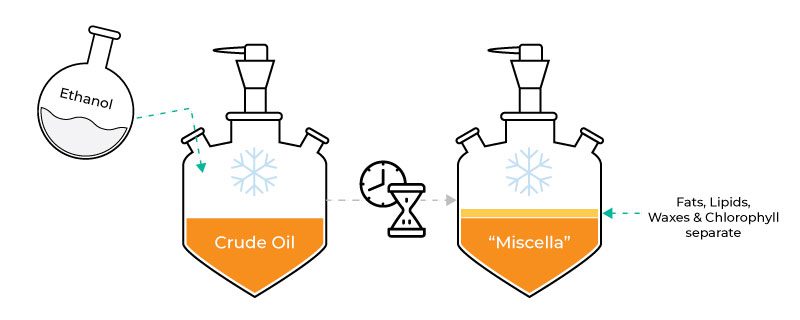

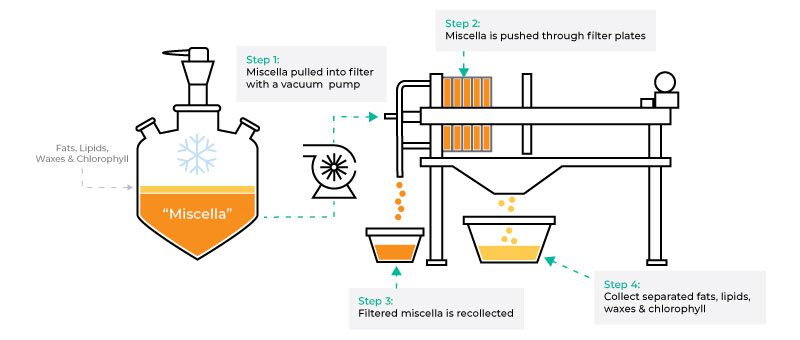

Winterization & Filtration Methods:

Winterization is a post-extraction technique that involves chilling the oil to precipitate waxes and other impurities. This additional step refines the oil, enhancing its clarity and preventing issues such as cloudiness in the final product. Winterization ensures a cleaner and purer oil for subsequent processing.

Various filtration methods, such as membrane filtration or activated carbon filtration, are employed to remove impurities. These methods exploit differences in particle size and chemical properties to selectively separate unwanted materials from the desired cannabinoids and terpenes.

Figure 4b. – Winterization Process in Cannabis Oil. [10]

Implications on Flavor Profile and Quality

Consistency & Effect on Flavor & Quality:

Achieving precision in impurity removal requires a deep understanding of the chemical properties of cannabinoids, terpenes, chlorophyll, and waxes. Solvent-solute interactions, solubility differences, and temperature considerations are factors that dictate the success of selective extraction.

The removal of impurities is not merely a procedural step; it significantly impacts the final flavor and quality of the oil. Scientifically guided pre-processing ensures that the essence of cannabinoids and terpenes is retained, free from the interference of undesirable elements.

Pre-processing impurity removal is a cornerstone of quality assurance. Consistently implementing precision techniques ensures that every batch of cannabis oil maintains a high standard, meeting consumer expectations for taste, clarity, and overall product quality.

By selectively extracting cannabinoids and terpenes while leaving behind chlorophyll and waxes, pre-processing becomes an art form that elevates the quality and purity of the final product. The scientific underpinnings of this process delve into the chemistry of solvents, the dynamics of selective extraction, and the careful orchestration of techniques like winterization and filtration. In this pursuit of precision, the canvas of cannabis oil is refined, ensuring that the symphony of flavors and aromas resonates in perfect harmony, free from the discordant notes of unwanted impurities.

Solvent Selection in Cannabis Oil Extraction

The choice of solvent emerges as a critical juncture in pre-processing, influencing the purity and safety of the final product. Solvents, such as butane, CO2, and ethanol, act as molecular architects, coaxing cannabinoids and terpenes from the plant matrix. This section delves into the intricate world of solvent selection, navigating the chemical landscape to optimize the extraction process with precision, ensuring both purity and safety in the final cannabis oil.

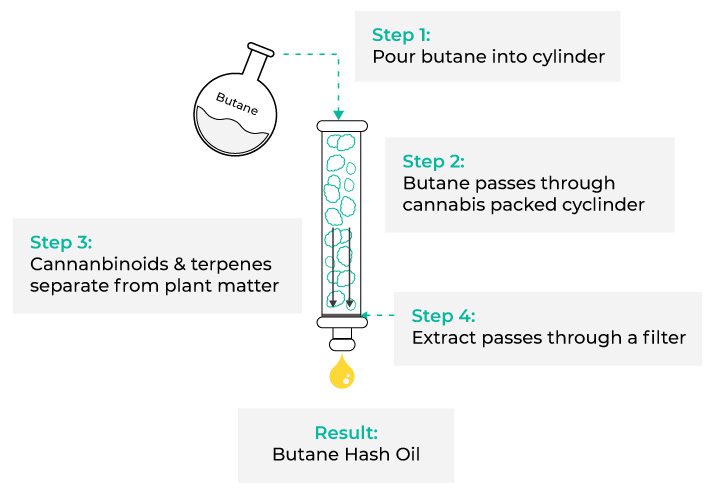

Figure 4c. – Process using butane oil to extract cannabis oil. [11]

Understanding Solvent Roles

Butane:

Butane is a hydrocarbon solvent known for its efficiency in extracting cannabinoids and terpenes. It is particularly effective in dissolving non-polar compounds, making it suitable for a comprehensive extraction. However, careful purging is required to eliminate residual butane, ensuring product safety.

CO2 (Carbon Dioxide):

CO2, in its supercritical state, acts as a versatile solvent with both gas and liquid-like properties. It offers precision in extraction, allowing for the customization of conditions to target specific compounds. CO2 is favored for its non-toxic nature and the absence of residual solvents post-extraction.

Ethanol:

Ethanol, a polar solvent, is renowned for its ability to extract a broad spectrum of compounds, including cannabinoids and water-soluble terpenes. Ethanol is considered safe and is easier to purge compared to hydrocarbons. However, its polarity can result in the co-extraction of chlorophyll, necessitating additional refining steps.

Advantages and Challenges:

- Butane:

-

- Advantages:

- Efficient extraction of cannabinoids and terpenes.

- Suitable for large-scale production.

- Challenges:

- Requires careful purging to eliminate residual butane.

- Potential for incomplete removal, impacting product safety.

- Advantages:

- CO2 (Carbon Dioxide):

- Advantages:

- Customizable extraction conditions.

- No residual solvents post-extraction.

- Challenges:

- Initial equipment setup cost.

- Sensitive to temperature and pressure changes, requiring precise control.

- Advantages:

- Ethanol:

- Advantages:

- Versatile extraction capabilities.

- Safer and easier to purge compared to hydrocarbons.

- Challenges:

- May co-extract chlorophyll.

- Less efficient in extracting non-polar compounds.

- Advantages:

Optimizing for Purity & Safety

Residual Solvent Considerations & Selective Extraction:

Achieving purity in cannabis oil involves meticulous consideration of residual solvents. Each solvent has distinct purging requirements, necessitating precise control of temperature and pressure during the post-extraction process.

Solvent selection influences the spectrum of compounds extracted. Tailoring the choice of solvent allows for selective extraction of cannabinoids and terpenes while minimizing co-extraction of unwanted elements, contributing to the purity of the final product.

Implications & Optimizations

Chemical Affinities & Thermodynamics of Solvent Extraction:

The choice of solvent is governed by the chemical affinities between solvents and target compounds. Understanding these interactions requires a deep knowledge of the polarity, solubility, and reactivity of cannabinoids, terpenes, and unwanted impurities. The extraction process involves the interplay of thermodynamic principles. Solvents operate within specific temperature and pressure ranges to optimize their efficiency. Scientifically guided solvent selection ensures adherence to these principles for consistent and reproducible results.

Consistency in Product Quality:

Solvent selection is a linchpin in quality assurance. Ensuring consistent and optimal extraction conditions across batches requires a scientific understanding of solvent dynamics, safeguarding product quality, and meeting regulatory standards.

The nuanced selection between butane, CO2, and ethanol involves an intricate dance of chemistry, thermodynamics, and safety considerations. Scientifically guided solvent selection is not just a technical decision; it is an assurance of precision, optimizing the extraction process to deliver cannabis oil that not only meets but surpasses the stringent standards of purity and safety in the ever-evolving landscape of cannabis product excellence.

Post-Processing & Winterization

While pre-processing is fundamental, post-extraction and processing remain vital for refining the final product. Winterization emerges as a melodic interlude, a post-extraction step that dances with cold precision to refine the composition. This process involves a careful chill, coaxing waxes and lipids to gracefully precipitate, enhancing the clarity of the oil and safeguarding against crystallization in the delicate embrace of vape cartridges.

This section delves into the scientific nuances of winterization, traversing the chilled realm to achieve heightened purity and stability in cannabis oil. Let’s briefly touch on the importance of these steps in ensuring the highest quality vape oils.

Figure 4c. – Post-processing diagram of winterization. [12]

Understanding Winterization Dynamics

Winterization and filtration after the initial extraction contribute significantly to the purity of distillate and other refined oils. The post-extraction phase is a critical component in achieving the desired characteristics in the final product. Innovations in this phase contribute to the overall quality and appeal of the final vape oil, a synergistic relationship between pre-processing and post-extraction steps in producing top-tier vape oils.

Precipitation of Waxes & Lipids:

Winterization exploits the temperature-dependent solubility of waxes and lipids in the oil. By subjecting the oil to cold temperatures, these compounds precipitate out, forming crystalline structures that can be separated from the liquid matrix.

The primary goal of winterization is to refine the oil’s composition by removing waxes and lipids. This selective precipitation enhances the clarity of the oil, eliminating cloudiness and particulate matter that may affect visual appeal and overall quality.

Optimal Temperatures:

The choice of temperature during winterization is crucial. It is typically performed at sub-zero temperatures, commonly around -20°C to -80°C, ensuring the effective precipitation of waxes and lipids while minimizing the impact on other desirable compounds.

The duration of winterization is a delicate balance. Insufficient time may result in incomplete precipitation, leaving residual waxes. Conversely, excessive duration may lead to over-precipitation, potentially affecting the oil’s texture and mouthfeel.

Preventing Crystallization in Vape Cartridges

Crystal-Free Vape Experience & Stability Enhancement:

Crystallization of waxes in vape cartridges can compromise the user experience. Winterization acts as a preventative measure, ensuring that the oil remains crystal-free and flows smoothly within the cartridge, avoiding issues such as clogging and uneven vaporization. Beyond clarity, winterization contributes to the stability of the oil. By removing potentially crystallizing components, the oil maintains its liquid state at a wider range of temperatures, providing a consistent and reliable vaping experience for consumers.

Figure 5a. – CQ5S with Stock Screw on Mouth-Pieces.

Implications & Direct Impact

Solubility Dynamic & Impact on Terpene Retention:

The solubility of waxes and lipids is intricately linked to temperature. Understanding the thermodynamics of solubility allows for precise control during winterization, ensuring the selective precipitation of undesired compounds. Winterization has implications for terpene retention. While it selectively removes waxes and lipids, careful attention is required to minimize the loss of volatile terpenes, which contribute to the aromatic profile and overall sensory experience of the oil.

Consistency in Winterization Protocols & Consistency:

Quality assurance in cannabis oil production involves maintaining consistency in winterization protocols across batches. Scientifically guided approaches ensure that each batch undergoes a refined process, meeting stringent quality standards.

The scientific mastery behind winterization involves an understanding of solubility dynamics, temperature control, and the delicate balance between clarity and terpene retention. This process not only contributes to the visual appeal and stability of the oil but also ensures a crystal-free and consistent vape experience, elevating the cannabis oil to a symphony of purity and precision in the hands of discerning consumers.

Testing and Analysis

Testing and analysis unfold as a meticulous examination, ensuring that the final product aligns with the highest standards of safety, potency, and efficacy. Rigorous testing throughout pre-processing and extraction becomes the sentinel guarding against impurities, residual solvents, and ensuring the product’s effectiveness. This section delves into the scientific intricacies of testing and analysis, where precision meets scrutiny to guarantee a cannabis oil that is not only safe but also a paragon of potency and efficacy.

Essential Components of Testing

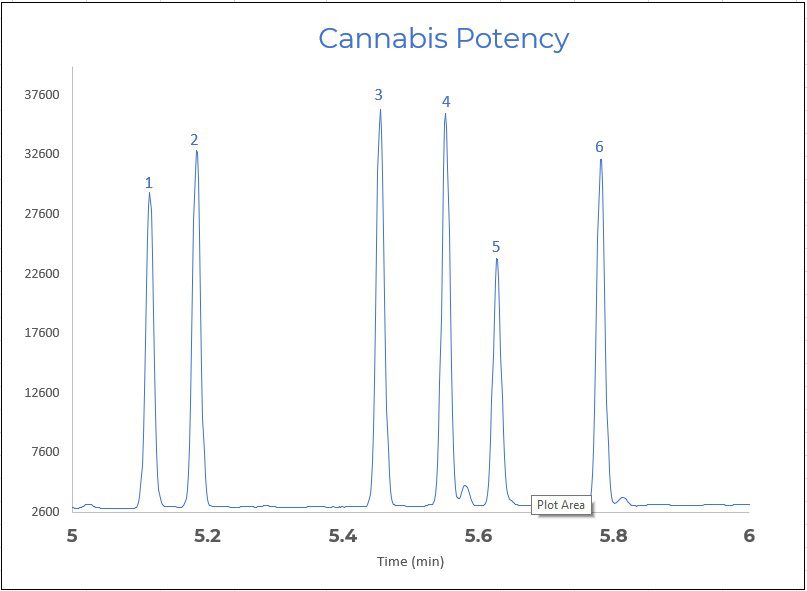

Potency & Residual Solvent Analysis:

Potency testing is a cornerstone in determining the concentration of cannabinoids, such as THC and CBD, in the final oil. Accurate quantification ensures that the product meets labeling claims and delivers the intended effects to consumers.

Residual solvents from the extraction process pose potential safety risks. Rigorous analysis is conducted to quantify and identify any remaining solvents, such as butane or ethanol, ensuring that the oil is free from harmful substances that could compromise consumer safety. Comprehensive testing includes the detection of contaminants, such as pesticides, heavy metals, and microbial elements. Identifying and quantifying these contaminants is crucial for ensuring that the final product is free from harmful substances that could pose health risks.

Figure 5b. – Chromatogram of a potency standard using helium carrier gas. [13]

Scientific Techniques in Analysis:

- High-Performance Liquid Chromatography (HPLC) – HPLC is a pivotal tool in potency analysis, allowing for the separation and quantification of cannabinoids. Its precision and sensitivity make it an indispensable technique for ensuring accurate labeling and dosage information.

- Gas Chromatography-Mass Spectrometry (GC-MS) – GC-MS is employed in residual solvent analysis, providing a robust method for identifying and quantifying trace amounts of solvents. Its ability to separate and analyze volatile compounds ensures the safety of the final product.

- Polymerase Chain Reaction (PCR) – PCR is utilized in microbial testing, enabling the detection of bacteria, molds, and other contaminants. This molecular technique ensures that the oil is free from harmful microorganisms that could compromise both safety and shelf life.

Implications & Consistency

Quantitive Accuracy & Validation Methods:

The accuracy of testing methods has direct implications for the quantitative representation of cannabinoids, solvents, and contaminants. Ensuring the precision of these analyses requires adherence to scientific principles and rigorous calibration procedures.

Validating testing methods is essential for establishing their reliability. Scientific validation ensures that the chosen analytical techniques consistently provide accurate and reproducible results, underpinning the reliability of the entire testing process.

Batch-to-Batch Consistency & Regulatory Compliance:

Testing is not a one-time endeavor but an integral part of quality assurance protocols. Ensuring batch-to-batch consistency through standardized testing procedures guarantees that each product adheres to the established quality benchmarks.

Testing is conducted following regulatory requirements, addressing specific safety and quality standards set by governing bodies. Compliance ensures that the product not only meets industry standards but also legal obligations. Rigorous testing and analysis contribute to label transparency. Accurate representation of cannabinoid content, absence of harmful contaminants, and compliance with safety standards build consumer trust and confidence in the product.

Through the lens of scientific precision, these analyses ensure that the oil is not only a manifestation of safety and purity but a testament to the potency and efficacy promised to consumers. The methodologies of HPLC, GC-MS, PCR, and others become the scientific compass guiding producers toward a product that not only meets the regulatory benchmarks but sets a new standard for excellence in the dynamic landscape of cannabis oil consumption.

Consistency in Cannabis Vape Oil Production

In the intricate realm of cannabis vape oil production, where precision and artistry converge, the twin pillars of consistency and reproducibility stand as sentinels, guarding the sanctity of every batch. Standardized pre-processing protocols become the scientific scaffolding, ensuring that each iteration mirrors the last.

Reproducibility emerges as the key, not only meeting but exceeding consumer expectations, and fostering trust in the burgeoning cannabis vape market. This section explores the scientific underpinnings of consistency and reproducibility, where every step is a calibrated dance toward excellence.

Standardized Pre-Processing Protocols

Role of Protocols & Influence on Extraction Efficiency:

Standardized pre-processing protocols act as a blueprint, delineating each step with precision. From the choice of starting material to the meticulous removal of impurities, protocols set the stage for a reproducible process. The consistency of pre-processing directly influences extraction efficiency. Standardized protocols ensure that the same parameters are employed across batches, allowing for a reliable extraction of cannabinoids and terpenes, and contributing to the overall quality of the final product.

Reproducibility as a Cornerstone

Meeting Consumer Expectations & Building Trust in the Market:

Reproducibility is the linchpin for meeting and surpassing consumer expectations. In a market where discerning consumers seek reliability, the ability to replicate the same high-quality product batch after batch is a testament to the commitment to excellence.

Trust is a currency in the burgeoning cannabis vape market. Reproducibility builds a foundation of trust, assuring consumers that each time they choose a product, they are embarking on a consistent and reliable journey, free from unexpected variations.

Reproducibility demands precision in controlling variables. Scientifically, this involves understanding the factors influencing each stage of pre-processing and ensuring that these factors remain consistent, from temperature and solvent choice to particle size during grinding. Scientific methodologies, such as statistical analysis and data-driven optimization, play a pivotal role in achieving reproducibility. Continuous monitoring and analysis of process parameters enable producers to refine protocols based on empirical evidence, ensuring ongoing improvement.

Quality Control, Education & Transparency

In-Process Quality Checks & Post-Process Validation:

Standardized protocols integrate in-process quality checks. These checks act as gatekeepers, ensuring that each stage of pre-processing aligns with the established parameters, and providing real-time feedback for adjustments if needed.

Reproducibility extends beyond the process to post-process validation. Scientific validation methods, including testing and analysis, ensure that the final product consistently meets potency, safety, and quality benchmarks, reinforcing the commitment to reproducibility. Educating consumers on the significance of standardized protocols and reproducibility fosters transparency. Transparent communication builds a bridge of understanding, allowing consumers to appreciate the meticulous scientific processes behind every vape oil product.

The establishment of standardized pre-processing protocols is not merely a procedural necessity; it is the foundation upon which the edifice of reproducibility stands tall. In the kaleidoscope of the burgeoning cannabis vape market, where consumer expectations are ever-evolving, the scientific imperative for consistency and reproducibility becomes the beacon that guides producers toward excellence. Each batch is a testament to the meticulous dance of protocols and the unwavering commitment to delivering a vaping experience that is not just consistent but a masterpiece of reliability in the hands of a discerning market.

Conclusion

Figure 5c. – Nova All-in-One Vape Unit.

In Summery

Closing Thoughts:

Pre-processing in cannabis oil extraction delves into the intricacies of multiple extraction areas and technical details, tailored to the specific requirements of different oils. These oils necessitate customized “pre-processing” approaches, often involving multiple “Pre-Processing” extraction areas, especially for further refined variants. For cutting-edge vape technology businesses, understanding these technical insights is indispensable. Embracing both pre and post-extraction processing methods aligned with quality goals, alongside careful selection and refinement of materials, is pivotal in ensuring the creation of a high-quality product.

The cannabis oil extraction journey is a dynamic process, continuously evolving with advancements in technology and methodology. Staying ahead of the curve requires not only a deep understanding of current pre-processing nuances but also anticipation of future developments. As a forward-thinking business, your commitment to innovation is essential for maintaining success in the ever-evolving cannabis and vape industry. Continual learning and adaptation to evolving techniques are paramount in this landscape where technology, science, and consumer preferences intersect.

Armed with the knowledge gleaned from this guide, you can embrace innovation and lead the charge in providing cutting-edge solutions in cannabis oil extraction for cannabis vape technology. Stay abreast of industry developments, cultivate a culture of continuous improvement within your organization, and position your business as a pioneer in shaping the future of cannabis consumption.

By understanding and refining “pre-processing”, & “Post-Processing” methods, you not only contribute to the success of your business but also drive forward the overall advancement of the cannabis and vape industry. As you navigate this dynamic landscape, remember that the pursuit of excellence and a steadfast commitment to innovation will differentiate your offerings, delivering a vaping experience that is not only enjoyable but also truly transformative for consumers.

Citations & Sources

- [1] Chambers, Adam. “Did You Know There Are Three Different Types of Cannabis Trichomes?” Prospiant, 11 Nov. 2020, www.prospiant.com/types-of-cannabis-trichomes/.

- [2] Happyana, Nizar, et al. “Analysis of Cannabinoids in Laser-Microdissected Trichomes of Medicinal Cannabis Sativa Using LCMS and Cryogenic NMR.” Phytochemistry, vol. 87, 1 Mar. 2013, pp. 51–59, pubmed.ncbi.nlm.nih.gov/23280038/, https://doi.org/10.1016/j.phytochem.2012.11.001. Accessed 28 Jan. 2022.

- [3] Alcohol and Drug Foundation. “Cannabinoids – Alcohol and Drug Foundation.” Adf.org.au, 28 June 2022, adf.org.au/drug-facts/cannabinoids/.

- [4] National Center for Complementary and Integrative Health. “Cannabis (Marijuana) and Cannabinoids: What You Need to Know.” NCCIH, 2019, www.nccih.nih.gov/health/cannabis-marijuana-and-cannabinoids-what-you-need-to-know.

- [5] “Pile of Shredded Marijuana with Little Bud on Top. Shredded Cannabis and Small Cannabis Bud Isolated on White Background. Stock Photo.” Adobe Stock, stock.adobe.com/images/pile-of-shredded-marijuana-with-little-bud-on-top-shredded-cannabis-and-small-cannabis-bud-isolated-on-white-background/335654764?prev_url=detail. Accessed 7 Feb. 2024.

- [6] Beckert, Julianna. “How to Grind Cannabis for Extraction | Mobius.” Mobius Trimmer, 28 Nov. 2022, mobiustrimmer.com/how-to-grind-your-cannabis-and-hemp-for-extraction/. Accessed 7 Feb. 2024.

- [7] (Lewis and Turner, 1978). Happyana, Nizar, et al. “Analysis of Cannabinoids in Laser-Microdissected Trichomes of Medicinal Cannabis Sativa Using LCMS and Cryogenic NMR.” Phytochemistry, vol. 87, 1 Mar. 2013, pp. 51–59, pubmed.ncbi.nlm.nih.gov/23280038/, https://doi.org/10.1016/j.phytochem.2012.11.001. Accessed 28 Jan. 2022.

- [8] precisionextraction. “Decarboxylation of Cannabis | What’s the Decarbing Process for Distillate?” Professional Extraction Equipment, 1 July 2020, precisionextraction.com/2020/07/decarboxylation-process-cannabis/.

- [9] “Business Icons Set for Business. Stock Vector.” Adobe Stock, stock.adobe.com/images/business-icons-set-for-business/355391644?prev_url=detail. Accessed 7 Feb. 2024.

- [10] Media, Blue Wheel. “Winterization Process in Cannabis Oil Extraction | Remove Waxes and Fat.” Professional Extraction Equipment, 15 June 2020, precisionextraction.com/2020/06/what-is-the-winterization-process-in-cannabis-extraction/.

- [11] precisionextraction. “BHO Extraction | the Basics of How Butane Hash Oil Is Made?” Professional Extraction Equipment, 15 Feb. 2021, precisionextraction.com/2021/02/the-basics-of-bho-extraction/.

- [12] Media, Blue Wheel. “Winterization Process in Cannabis Oil Extraction | Remove Waxes and Fat.” Professional Extraction Equipment, 15 June 2020, precisionextraction.com/2020/06/what-is-the-winterization-process-in-cannabis-extraction/.

- [13] Granite. “Cannabis Testing Solutions | GC & LC Cannabis Analysis.” SCION Instruments, scioninstruments.com/us/markets/pharmaceutical/cannabis/. Accessed 7 Feb. 2024.

Hey, stumbled upon this post, super informative and easy to read, recommending it to my buds. Thanks for sharing the knowledge!

A nice read for anyone diving into cannabis oil extraction and refining. It breaks down the process in a pretty relatable way, makes it easy for beginners like me.