When a company is ready to start filling vape cartridges and actively trying to decide whether to use manual filling strategies or to go automatic, there are many considerations depending on the business’ priorities. We developed this article with the hope that you will find the below information insightful and supportive in making those decisions for your business.

Within the oil & concentrate sectors of the industry, new and innovative products are continually rolling out and it’s hard to distinguish what is really the best fit for your business.

Filling machines are an important part of this sector. We believe the industrial revolution shows us a thing or two about scaling and optimizing production. In this article, we will be reviewing some of the strategies we have found to be most effective and efficient.

Topics

What is a Cartridge Filling Machine?

Cartridge filling machines are designed to fill vape cartridges with exact dosages of concentrates, such as various blends of THC oil, CBD oil, and Live Resin. After being filled, consumers attach these cartridges to batteries in order to heat up and vaporize the oil to be inhaled. The machines come in many different sizes and shapes and most can be custom tailored to suit your business’ needs.

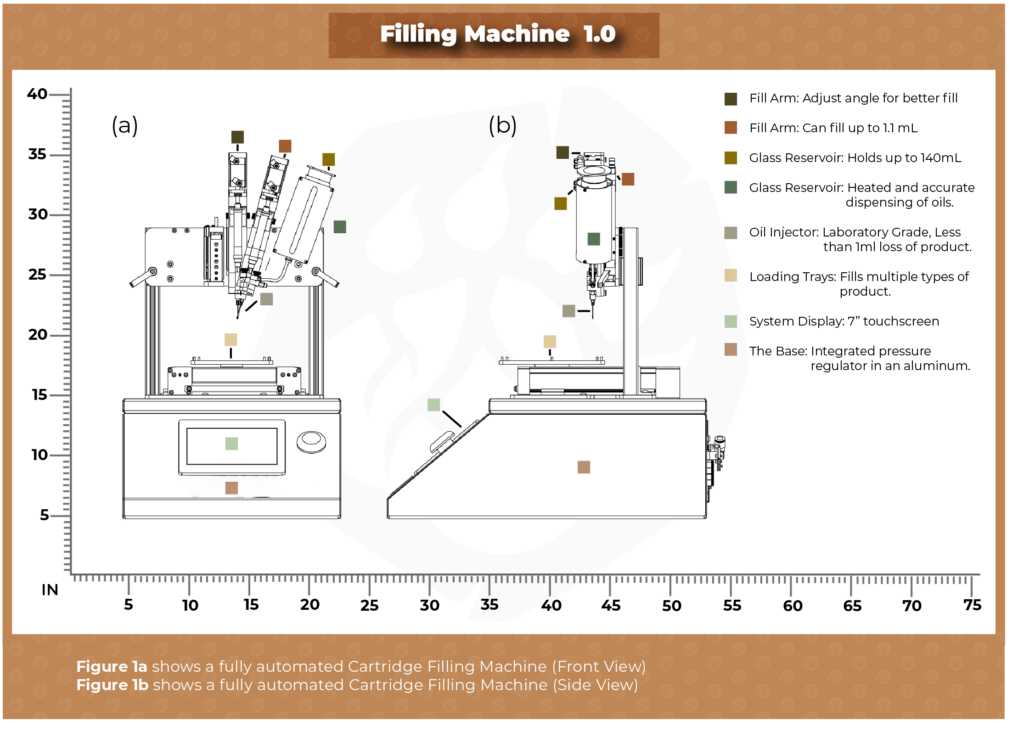

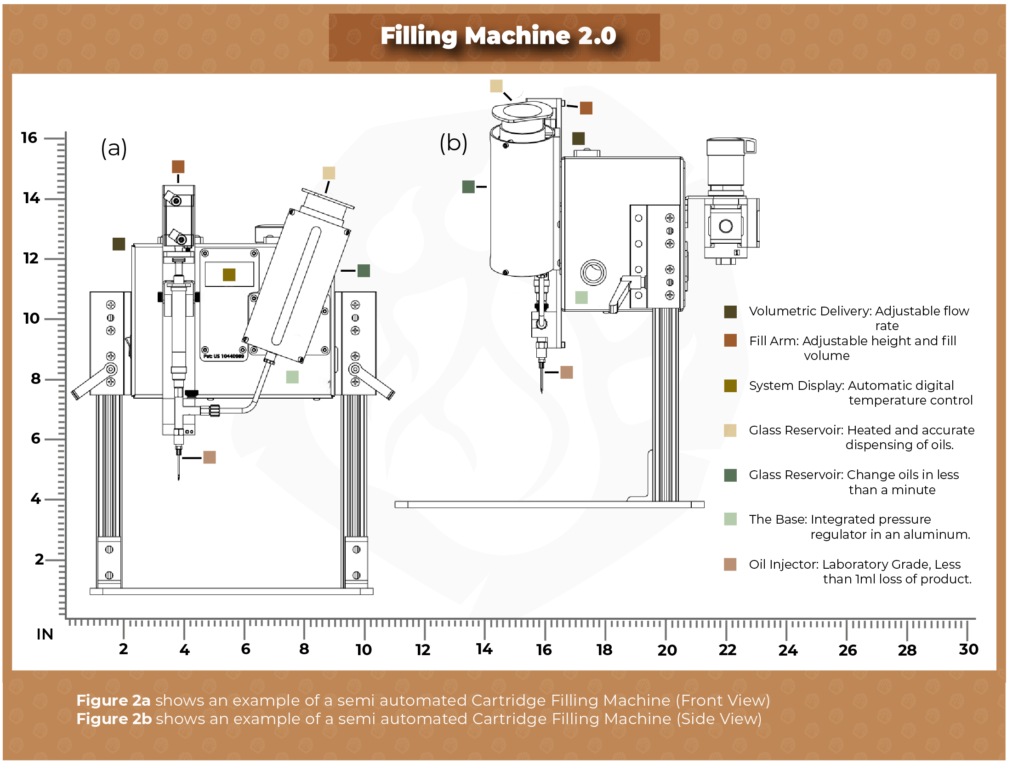

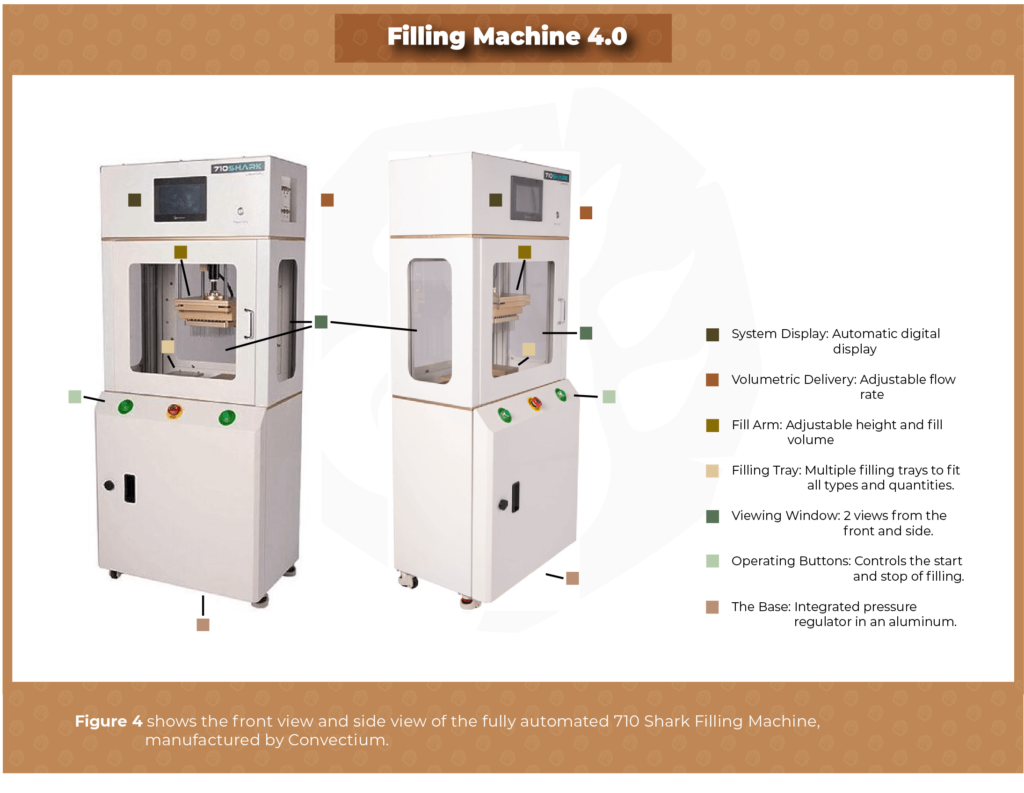

The main hardware that comprises the filling machines vary from brand to brand but most have an oil chamber that can be filled up and is used to dispense the oils, a nozzle that injects the concentrates into the cartridges and a holding tray to put the cartridges in while filling them. Some are equipped with a heating element to make the distribution of more viscous oils easier while others use a piston to force enough pressure into the line to get the same results. The bigger filling machines also can come equipped with an automatic capping mechanism that reduces the amount of oxidation and leakage within each vape cartridge [1].

Types of Filling Machines

There are three different types of filling machines on the market: Manual, Semi-automated and Fully-automated fillers. Manual hardware can be used and typically fills one cartridge at a time, while utilizing a smaller amount of space and keeping the start-up investment costs likely much lower [2]. Typically the manual filling methods involve tools such as syringes and hotplates to keep oil viscous enough to work with.

Manual filling requires a heating device; usually the type of heating device is dependent on the oil being used. Since distillate has a higher viscosity, it benefits from being continuously heated throughout the entire process to prevent clogs while filling. Live resin, on the other hand, has cannabis-derived terpenes that are especially sensitive to heat, so emphasis should be placed on how long the heat is applied and how much heat is being distributed.

Regardless of the oil being used, all start in jars typically made of glass. These jars are then placed in what is essentially a large convection oven and heated until the oil is a liquid substance. For distillate, the jar is then placed on a hot-plate to keep the oil heated underneath, and a heat gun is also used to keep the sides and top of the jar heated. For live resin, the jar is placed on a hot-plate, but no additional heat gun is used as too much heat could ruin the product.

A thermometer may be used to precisely measure the temperature of the oil with live resin in some cases. A scale is a very important tool when manually filling, as different compliances of state laws require that cartridges cannot be filled to capacity due to high potency. Thus, a scale helps measure the weight of oil being added to each cartridge.

Another important tool for manual filling is a syringe. Syringes are usually made of glass, and industrial grade packaged 3-10ml syringes are popular among manual filling. Smaller syringes are popular for heating purposes, as a 10ml syringe can cause the oil to clog and overall slow the whole process.

Something important to note is that some industrial grade syringes can have lubricant, which in turn can cause a foggy appearance on the cartridge that is being filled. While harmless, this foggy appearance can make the oil look off to consumers. Manual filling also has a greater chance of introducing contaminants to the filled cartridges, as it not only requires an operator, but it also is a little slower than its counterparts.

Then there are the Automatic Filling machines (See Figure 1.0). These can fill roughly 2,000 vape cartridges within an hour (amount varies by machine), ramping up production speed while limiting the contact with the operators [3].

Each type of filling machine has merit, but more and more companies are switching over to fully automated filing systems. They are more pricey up front but often when taking into consideration the hourly rate of manual labor, automatic machines typically pay for themselves on calculable ROI periods, which vary case by case, but normally within a couple of operational years.

“As a fully automated system, the pump, fill volumes, and environmental controls are all controlled by software and require little-to-no intervention from an operator once a production run has been fully loaded and processed to begin.” [4]

There is also less chance of contaminants entering the filled tanks and more consistency in volume distribution. Most automated machines also come equipped with capping systems that allow for faster and more reliable sealing of the filled products.

However, automatic machines are not infallible. One of the largest things to be wary of with automatic machines is the risk of waste increasing if the machine is not properly set up, calibrated and maintained. And as you can imagine, the employee needed to oversee a filling machine will typically be of higher skill and cost than a manual laborer.

An automatic filling machine will also keep filling even when a possible error is occurring, thus increasing the risk of wasted product. Some automatic filling machines have waste preventative settings, but we have yet to find one that covers all possible risks.

Overall, automatic filling machines are, in most cases, ideal for high volumes of production and allow the cost of the finished product to be greatly reduced versus manual filling.

If your company is just starting out or does only small-batch distribution, manual filling guns might be the way to go, at least to start. While there is more room for error because there are more human touch points, the cost is much less upfront and takes up the minimal amount of space. Automated machines can weigh anywhere from 34lbs to over 300lbs [2] and may require special stations for setting up. The only space manual filling takes up is the space the person occupies.

The happy medium between these two options is the semi-automatic filling systems (See Figure 2.0). These are ideal for mid-level to bigger companies that need to fulfill more quantities quickly but don’t have the space or budget for a fully automatic machine. Semi-automatic machines can fill small batches at a time, but usually require an operator to be present to hold the cartridge up to the nozzle and to cap the filled cart.

Semi-automatic machines have their own issues. One issue is due to the period of time it takes to manually cap the cartridge once it is filled. Oxidation can occur if the oil is left open to the air and leakage is more likely to occur due to the oil settling before capping. When capped quickly, the cartridge creates a vacuum effect, holding the oil in place and defying gravity. On the plus side of semi-automatic filling, the machines tend to be smaller and more cost-effective while increasing the volume of production [5].

What to Look for When Purchasing a Filling Machine

As with any major purchase, there are a few things to take into consideration. Researching different machines is a key part to making an informed decision. Oil viscosity and quality, product type, price, warranty and servicing fees all should be taken into consideration. Size of lab space and volume of production should also play a part in the decision.

While each method has its own advantages and disadvantages, the decision to go with one over the other really comes down to how big of an operation you are running and how much product you are trying to move in any given time.

Even though they are less costly upfront, manual machinery tends to be more costly in the long run due to the need for human operators. There are also more chances of contamination and inconsistencies in filling volume whereas with semi or fully automatic machines, those issues tend to only arise 1% of the time versus the 2% of manual filling [6].

Capping Machines

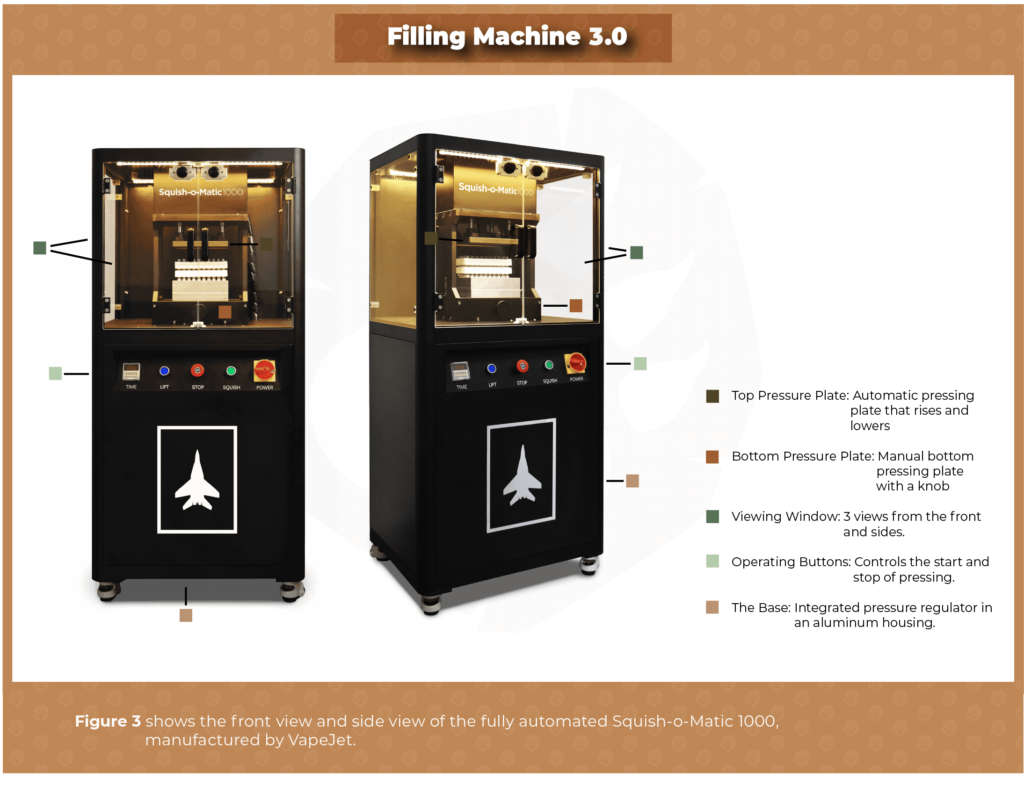

Alongside the filling machines, capping methods can also be completely manual, semi-automatic, or completely automatic. Some of these semi-automatic and automatic capping machines can come separately from the cartridge filling machine, such as ATG Pharma’s MonoBlox Cartridge Press [7] or Vape Jet’s Squish-o-Matic 1000 (See Figure 3.0) [8]. Others, like CNC Packaging’s C900 Series [9] have the ability to both fill and cap multiple cartridges in one go.

There are two distinct types of caps for cartridges currently: screw-on and press-on. Screw-on, otherwise known as twist-on caps, are exactly how they sound; the cartridge’s center-post is threaded at the top, and a cap for the cartridge is screwed on once the cartridge has been filled. These caps can be added manually using a drill tool, or a machine such as the C900X from CNC Packaging [10] twists the cap on immediately following being filled. One reason screw-on caps are preferable is that they are arguably more eco-friendly, as an operator can refill the cartridge once it is empty. However, they are more prone to leaks than press-on caps, especially when used multiple times, since the threads on the center-post can be stripped.

Press-on caps, on the other hand, are pressed onto the filled cartridge. Manual pressing involves an operator using a rubber mallet, while capping machines, such as the ones previously mentioned, utilize a hydraulic press. A main reason press-on caps are preferable is that press machines are more readily available than machines for screw-on caps. Since they also have the ability to cap multiple cartridges at once, production volume drastically increases while simultaneously cutting down on labor costs and decreasing oxidation. However, center-posts in cartridges can be angled slightly due to manufacturing defects, and using a press-on capping machine on one of these defected cartridges can cause the glass to crack or shatter.

Top Filling Machines on the Market

There are many Vape Cartridge filling machines to choose from on the market. Two of the top manufacturers are Thomson & Duke and Convectium. The 710 Shark by Convectium (See Figure 4.0) is probably the most popular within the industry. It is fully automated and can handle approximately 100 cartridges per minute [11]. What makes the Shark so popular is its ability to fill multiple types of vape cartridges. From glass to polycarbonate and all-ceramic to stainless steel, the Shark in general, can handle them all without much difficulty.

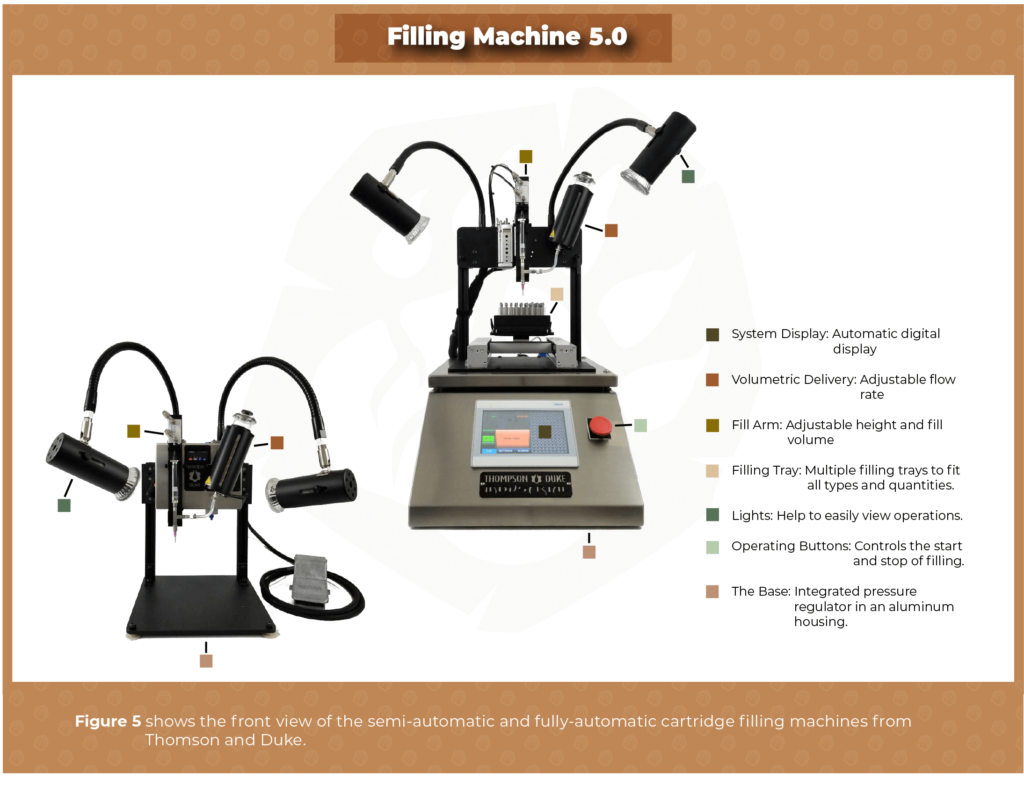

Thompson and Duke have a few options for filling machines based on if the need is for semi-automatic or fully-automatic (See Figure 5.0). The ACF1 Automatic Vaporizer Filling Machine is versatile and can handle almost any type of cartridge, POD, syringe or jar [12]. It comes with an easy-to-use 7” touch screen to control temperature, fill speed, get updated status of the process and real time diagnostics.

Thompson and Duke’s Semi-automatic filling machine is the MCF1 Semi-Automatic Vaporizer Filling Machine [12]. Operated by a foot press, similar to a sewing machine foot peddle, this machine does require more manual operation but can handle almost all cartridges, PODs, syringes and jars, much like their fully-automated machine.

The bonus with the MCF1 machine is that it is lightweight and portable, enabling it to be used on any flat surface in any small area. Most machines on the market that are portable tend to have issues but the reviews seem to reflect that the MCF1 is very sturdy and gets the job done smoothly.

To put it simply, we are human and error tends to occur when we are a part of the process. Minimization of human touch points creates a more sterile and accurate filling scenario. Whichever method you decide on, make sure to do research before purchasing!

Sources:

[1] https://credencefilling.com/blog/capping-and-filling-systems/

[2] https://www.healthcarepackaging.com/markets/cannabis/article/21139637/6-Considerations-for-automating-cannabis-filling

[3] https://credencefilling.com/resources/understanding-cartridge-filling/

[4] https://www.theblincgroup.com/filling-automation-the-art-of-customer-success-and-building-an-efficient-process/

[5] https://www.greentanktech.com/education/cannabis-oil-filling-machines/

[6] https://www.petitionthem.com/how-does-a-vape-cartridge-filling-machine-work/

[7] https://www.atgpharma.com/products/semi-automatic/cartridges#widget8

[8] https://vape-jet.com/squish-o-matic-1000/

[9] https://cncpackaginginc.com/c900pf

[10] https://cncpackaginginc.com/c900x

[11] https://www.convectium.com/automated-filling.html

[12] https://thompsondukeindustrial.com/acf1-automatic-vaporizer-filling-machine/