Thanks to an economically driven evolution for vape businesses to stand alone, or to meet moving target compliance requirements, rapid Vape Cartridge development is happening right before our eyes! Cartridges are small yet complex hardware devices in the smoke-vape industry.

Topics

Introduction

Fundamentally, a Cartridge is a small oil/wax/resin holding device with a multitude of components that now come in an increasing volume of variances from size, complexity, coil types, material types, shapes, and colors.

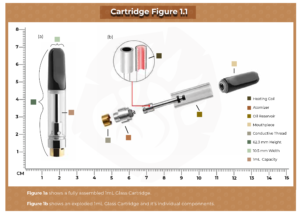

All of these components and more factor into the look, feel, and experience from cartridge devices. (See Figure 1.1 for the breakdown of cartridge parts)

It’s good to first point out that a customer’s vaping experience is not solely dependent on the medium’s holding device – aka Cartridge – another contributing factor is also the battery component that energizes the cartridge itself during use.

A vape battery has its fair share of influence on the overall vaping experience for the end consumer. As you can imagine a cartridge receiving too high a voltage or too low a voltage can have an effect on the product and thus the entire vaping experience.

The base of a cartridge holds the atomizer, or heating elements, which includes the coil. The middle of the cartridge is known as the tank/reservoir and holds the concentrated oils. Lastly, you have the mouthpiece where you inhale the vapor from.

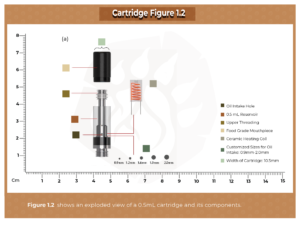

See more detail in Fig 1.2 below:

Different Mouthpiece Options

One of the first major questions to consider when choosing a cartridge is the mouthpiece. There are many types and shapes of cartridge mouthpieces to offer to customers. Similar to the base and tank of a cartridge, there are options of materials for a mouthpiece. The four basic materials are plastic, ceramic, metals, and wood, as shown in Figure 2.1.

Plastic and Ceramic are the most popular choices because they are cost-effective and easy to produce. Ceramic is less porous and is BPA Free, making it a customer-preferred choice overall. Plastic can be BPA-free but is a more porous material and reportedly affects the taste of the inhaled vapor after repeated use.

Both types of mouthpieces can be customized by adding different colors to the mold when they are being created.

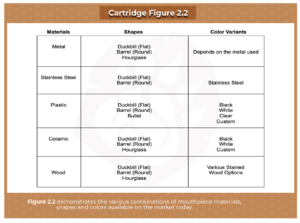

Each type of material also comes in different shapes, such as the duckbill (flat), round (barrel-shaped), hourglass, or bullet-shaped. Refer to Figure 2.2 for a list of different materials and the shapes that are offered.

Personal preference is all about trying the various shapes and seeing what suits your brand ideals. Having a few options allows the consumer to have more variety to purchase. The cartridges Bear Rootz offers come with a base mouthpiece that can be upgraded to different materials and shapes to suit branding needs.

What sizes are available?

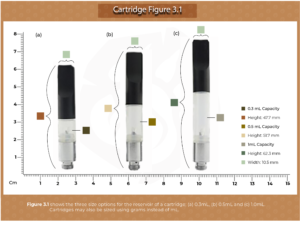

The next decision to make is about the sizing of the cartridge. There are generally three main sizes available on the market, 0.3 ml, 0.5ml and 1.0ml, (see Figure 3.1). The sizes are also referred to as a third gram, half a gram, and full gram depending on the manufacturer.

The bigger sizes tend to last longer since there is more concentrated oil in the reservoir. If the consumer base is avid users of vape pens, perhaps the bigger cartridge would be a better choice. Sizing could also come into play with cost. In some states, a 0.5 gram costs the same as a full gram does in another state. This is due to sales tax, state regulations, and the cost of manufacturing.

If you choose to go with a polycarbonate reservoir, it might be more cost-effective to have full gram options available to your consumers. Glass might cost a bit more but ultimately feels higher quality. Again, it really depends on the balance between cost and brand alignment.

To the naked eye, the general population usually cannot distinguish between a high-quality polycarbonate cartridge and a glass cartridge. Size is what is noticed immediately when purchasing products.

Myth: The 1ml cartridge will not work as well as a 0.5ml or 0.3ml cartridge because of its size.

Fact: All sizes of cartridge reservoirs will work the same and produce the same experience because the heating element within each cartridge is designed for that specific size. The main differences are how much oil concentrate is stored and the cost to create the cartridge.

Myth: Some Reservoirs are not filled up all the way.

Fact: Reservoirs are filled based on weight so there is no difference from one cartridge to another of the same size. The difference in levels that may be noticed is known as Head Space. This occurs when some of the oil concentrate settles into the coil chamber. The same amount is available to vape but gravity is at work, creating the appearance of a partially filled cartridge.

Glass or Polycarbonate Tank?

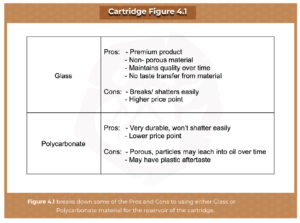

Over time, different consumers develop preferences for certain material types, styles, feel, and shapes. The most common historical initial consideration is body material variance.

These material variances have two primary categories: Glass & Polycarbonate, a type of hard plastic. To the naked eye, it is really hard to tell one apart from the other. The majority of customers won’t be able to tell the difference and, as with all things, there is a give and take.

This is referring to the outer casing of the Cartridge itself. The chart below (Figure 4.1) lists some of the basics to consider when purchasing for your company.

Atomizers & Coils

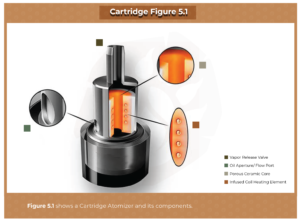

Atomizers and the heating coils (see Figure 5.1) are important to discuss as well. Some of the atomizers have a base of ceramic while others are copper, brass, stainless steel, or even quartz. Why are the materials used for the heating elements important? Well simply put, some of the materials used can break down or leach into the oil concentrates over time. The materials used also have different cost points. Stainless steel, for example, will hold up longer but costs more to mold while brass doesn’t hold up as well, over time, but is more cost-effective. Quartz heats up more evenly and is non-porous, compared to ceramic. Copper, while cost-effective, tends to break down or corrode more quickly.

Cartridges used to be made with wicking material wrapped around the metal coil but industry leaders are stepping away from this practice and using ceramic or quartz coils. The coil of a vape cartridge is wrapped in a cylinder of ceramic, brass, stainless steel, or quarts and protects the coil from direct contact with the oils to allow for a longer life span.

Different material types last different lengths of time. Ceramic is popular in the industry as it is a cleaner coil that can manage to get hotter and lasts longer than the metal coils tend to. The ceramic coils are also less likely to be broken down by fillers and sugars that are introduced into concentrates for flavor. Without the need for wicking materials, ceramic and quartz coils do not have a burnt aftertaste at the end of the cartridge, which can sometimes happen with copper, brass, and stainless steel.

Quartz is breaking into the industry as the newest material used for atomizer coils. Since it is not a metal but is conductive and heats evenly, there is little worry of leaching into the oils. Quartz meets all of the requirements as well as being compliant with current industry standards.

Ohms are also important to take into account. OHM is the measure of resistance from the Atomizer. The higher the ohm rating of a heating coil, the less power will pass through it.

Three factors establish the Ohms: Resistance, Voltage, and electrical current (amps). Each of these can fluctuate, with the exception of resistance. The resistance is a set number but voltage and amps can change, causing its counterpart to get higher or lower. If either the voltage or current gets too high, the resistance can give out and the coil can become damaged.

Ceramic and quartz coils have higher resistance and can be used with variable voltage settings. Sub-ohm (less than 1.0 ohm) coils such as brass and copper are much better suited for fixed voltages that are on the lower end of the scale (3.7 voltage and lower).

Through Holes & Flow Patterns

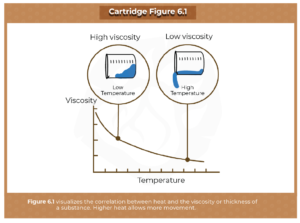

The next thing to think about is the viscosity of the oil your company sells or manufactures. Viscosity is the resistance to movement a liquid has. So a higher viscosity means a thicker substance. The thicker the oil, the higher the voltage needed to vaporize it. Some pens have variable voltages while others are at a set voltage and may not be suitable for thicker substances.

Depending on what type of oil the cartridges are filled with, the aperture is important too. Aperture refers to the holes at the bottom of the reservoir that allows the oil to seep into the coil chamber.

This movement of the oil and airflow is known as the capillary action. Capillary action is what ultimately gets the cycle moving when heat is introduced. The three forces happening to create capillary action are adhesion, cohesion, and surface tension. These three factors are influenced by the type of atomizer materials and of course, the aperture holes.

The bigger the holes are, the higher the volume of oil that can flow through to the coil. Industry standards are 2.0mm holes. If the concentrate being sold is thinner, however, a smaller aperture may be used to avoid any unnecessary leakage. The 2.0mm allows most concentrates of varying viscosity to flow through to the coil. If the hole is too big, the oil will burn off faster and last a shorter period of time. (See Figure 6.1)

Threading and Base Types

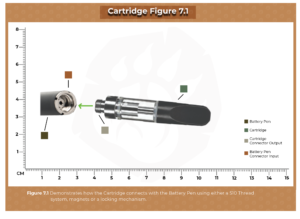

One of the parts of the cartridge to inquire about, when purchasing in bulk, is if the Cartridge threading is compatible with the vape pen batteries offered to consumers. There is nothing worse than purchasing thousands of Cartridges only to find they have the wrong connector for the pen battery being stocked.

Most manufacturers use a standard 510-thread system (see Figure 7.1). This refers to the screw on compatibility of the thread on the bottom of the Cartridge and the top of the battery.

Other base types include magnetic connectors and lock-in types that twist to secure the Cartridge locking mechanism to the battery. These are less used but have their own appeal. 510 Threads can strip over time from being screwed in so many times but a magnet will never lose its polarity.

While magnets can be disconnected by accidentally hitting them, the locking type of base is valuable in that it twists and clicks in, not allowing it to give at all. Each variation works well but the 510 Threading is a preference consumers ultimately have given the most positive feedback on.

Recap

Choosing the right cartridges for your customer comes down to finding that sweet spot between cost and quality that aligns with the brand it represents. Many existing brands prefer to use polycarbonate as the casing because it costs less to make and also is less likely to get damaged during shipping and stocking of the product, however, glass tanks are getting more and more popular because they are perceived as the “higher quality” cartridge option.

There are many combinations of mouthpieces that are offered for wholesale and many more are always being created. Materials range from ceramic and plastic, as the most used, all the way to metal and wood. The shape is of personal preference but the two most commonly purchased and sold are the Duckbill-shaped mouthpieces and Barrel-shaped mouthpieces.

The viscosity of concentrate oil and coil resistance (OHMs) also play a big part in how a cartridge works. All of these elements come together to create a unique experience within a small form. Now that the fundamentals of a cartridge and its components have been broken down, be confident in buying Vape Cartridges and cartridge mouthpieces that your brand can stand behind.

Love the blog & the site, keep the content coming!